Bullet Aerodynamics - .223 Remington

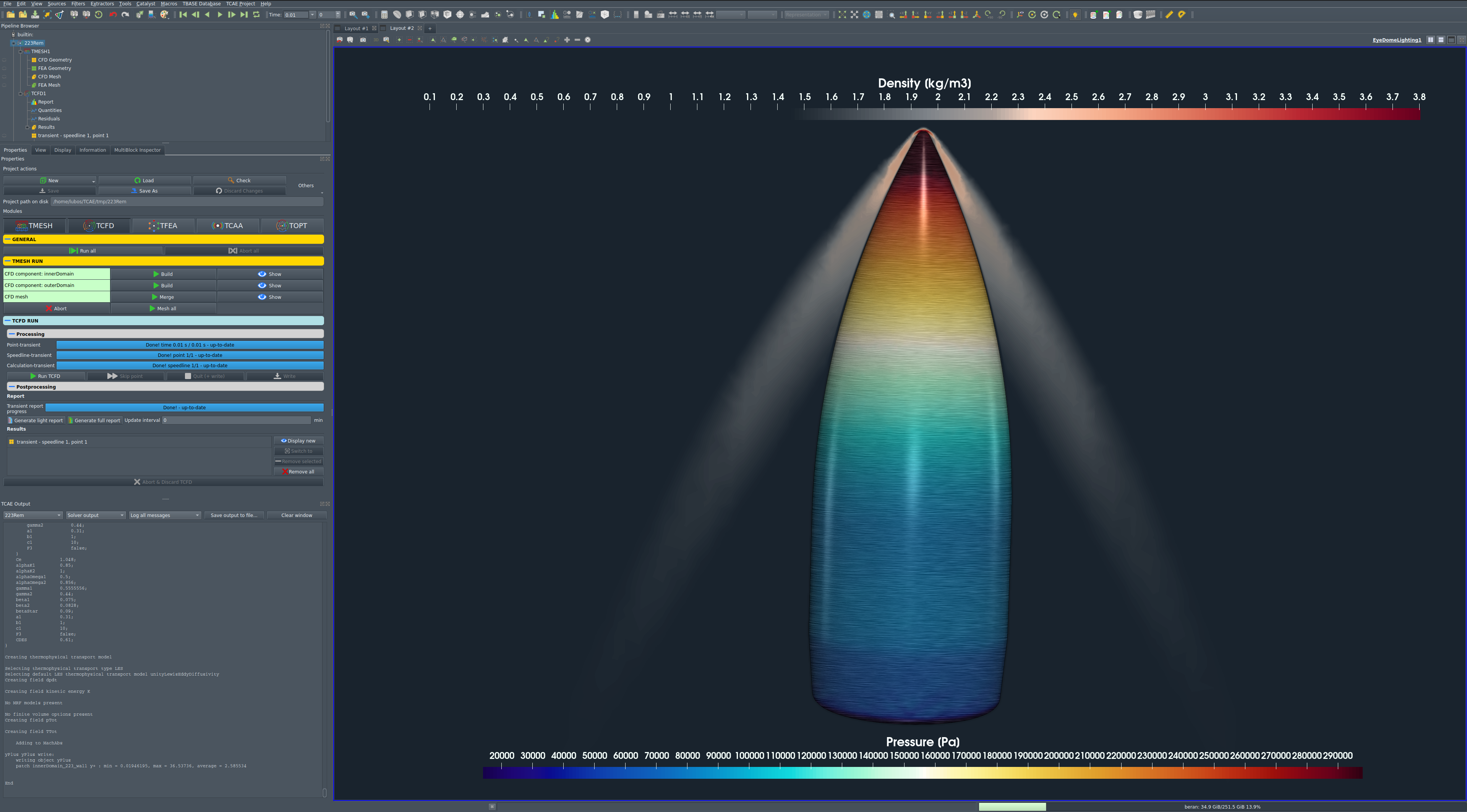

Supersonic Bullet – Simulation workflow

This case study shows a comprehensive CFD + FEA simulation workflow using TCAE

Bullet .223 Rem - Introduction

In this project, we simulated the external aerodynamics of the .223 Remington bullet, traveling at supersonic speeds of 900 m/s. The simulation focuses on capturing critical flow phenomena to analyze the bullet’s performance and aerodynamics in detail. The simulation workflow, case setup, simulation & postprocessing are run in the simulation environment TCAE.

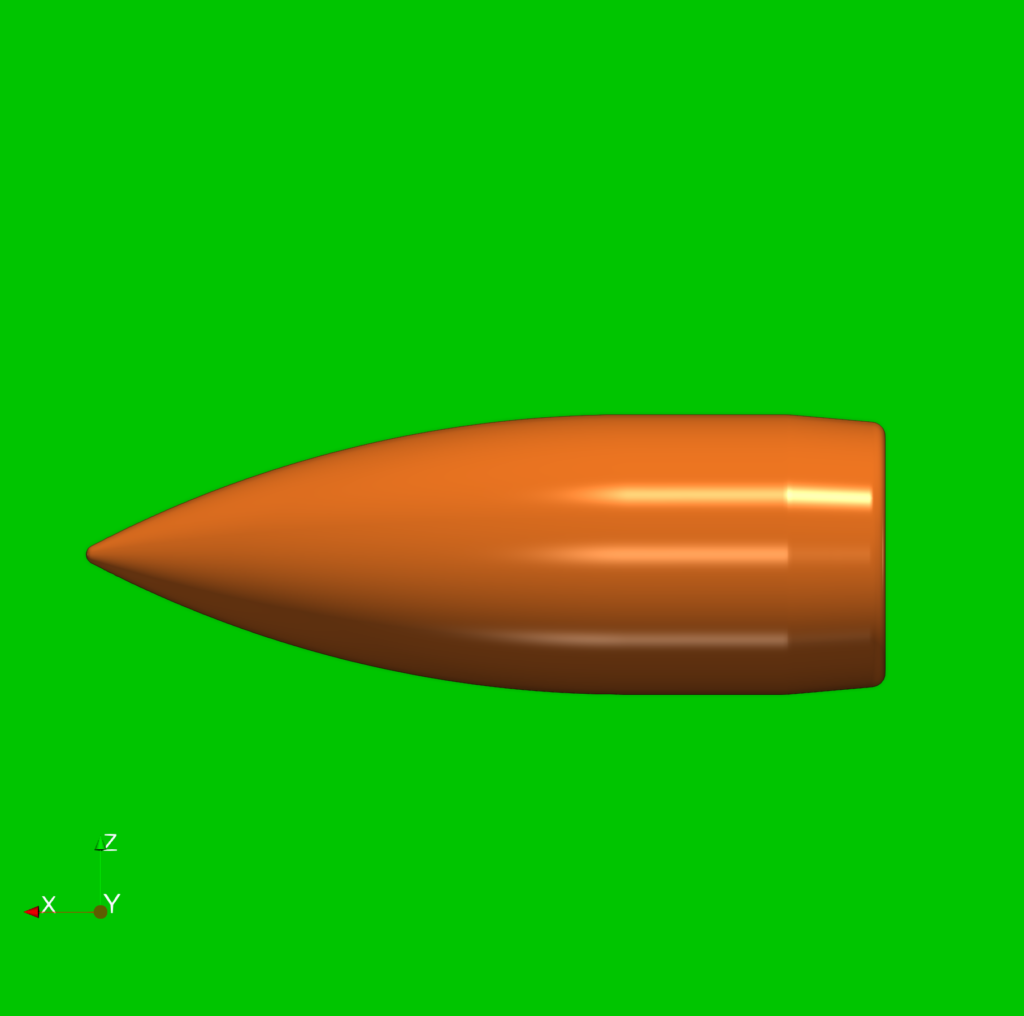

Bullet .223 Rem - Geometry Description

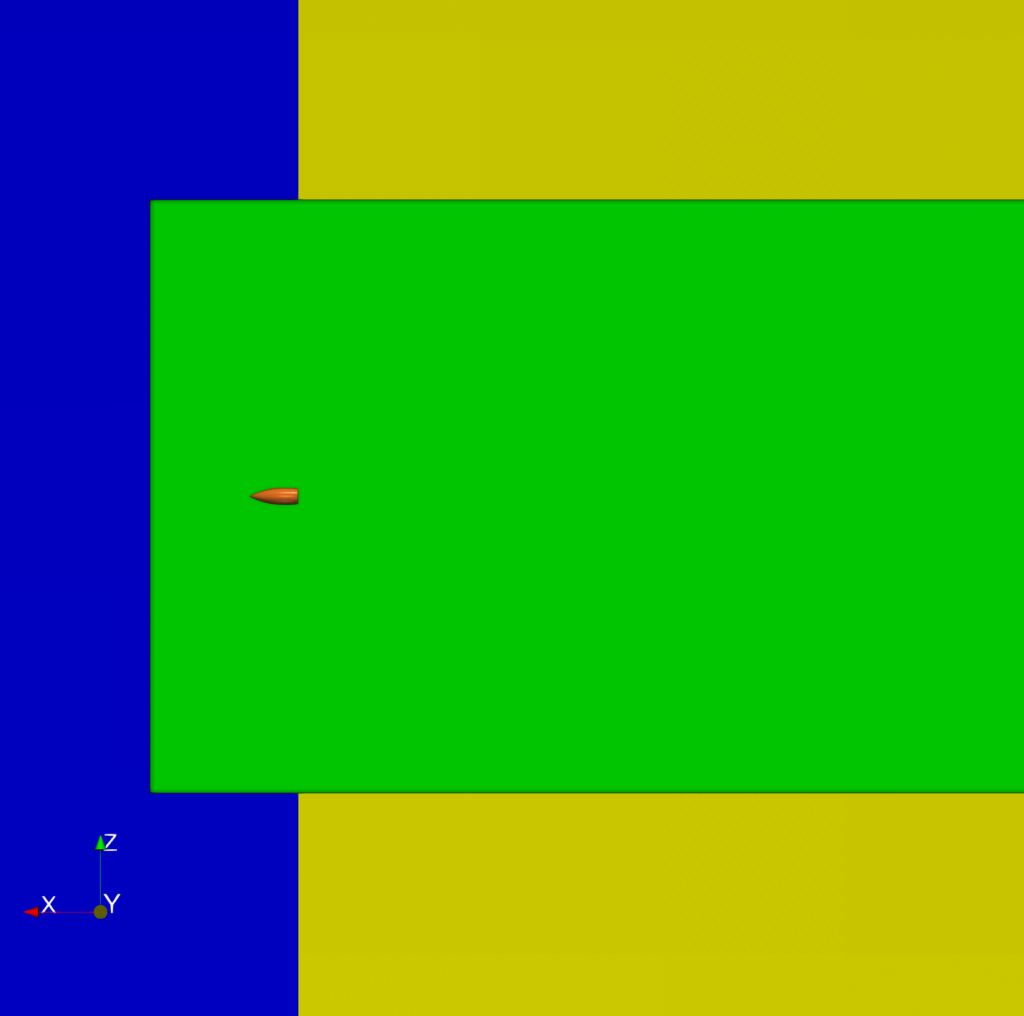

The .223 Remington bullet is a high-velocity, small-caliber projectile commonly used in rifles. It is typically constructed with a lead core for density and energy retention, and a copper (cuprum) jacket for structural strength, reduced barrel wear, and improved aerodynamics. This combination of a lead core and copper coat ensures high performance, stability, and effectiveness in both sporting and tactical applications.

Bullet Geometry Description

The geometry of the .223 Remington bullet can be summarized as a spitzer ogive tip, cylindrical shank body, and boattail base, all carefully designed to optimize aerodynamic performance and stability during supersonic flight.

Ogive (Nose or Tip) 🔼

The bullet’s forward section, often referred to as the ogive, has a smooth, curved shape designed to reduce aerodynamic drag. The ogive can be described as a spitzer shape (a sharply pointed tip), which enhances the bullet’s aerodynamic efficiency for supersonic travel.Shank (Body) 📏

The shank is the cylindrical midsection of the bullet, maintaining a consistent diameter along its length. For a .223 Remington bullet, the diameter is 0.224 inches (5.7 mm). The smooth cylindrical surface of the shank ensures stability when the bullet engages the rifling in the gun barrel.Boattail (Base) 🛳️

At the rear, the bullet typically features a boattail design—a tapered, conical shape that reduces drag by minimizing turbulence in the wake. This design improves the bullet’s aerodynamic stability and helps maintain velocity over long distances.Overall Proportions 📐

The bullet has an elongated structure, with the ogive smoothly transitioning into the shank and tapering into the boattail base. This streamlined geometry allows the bullet to achieve supersonic speeds with minimal air resistance.

Bullet .223 Rem - Simulation Input

A typical input for a detailed simulation analysis is a 3D surface model in form of an STL surface. For CFD simulation, it is needed to have a simulation-ready surface, which is a closed watertight model (sometimes also called waterproof, or model negative, or wet surface). Similarly, for TFEA simulation, it is needed to have a closed surface model of the solid of the impeller in form of a single STL surface.

In general, there are multiple ways how the CAD model can be created. The CAD model of the CAD can be generally created in any standard commercial CAD software manually or in an automated way via a parametric model. The surface model can be created in open-source software like Salome, FreeCAD, or OpenCascade.

An existing CAD model is typically received in the STEP or IGES CAD file format. Original CAD files are usually too complex for comprehensive CFD and FEA simulations, so certain preprocessing (cleaning) CAD work is generally needed. While the original CAD model for this project was simplified and cleaned using Salome open-source software, any other standard CAD system can be used instead.

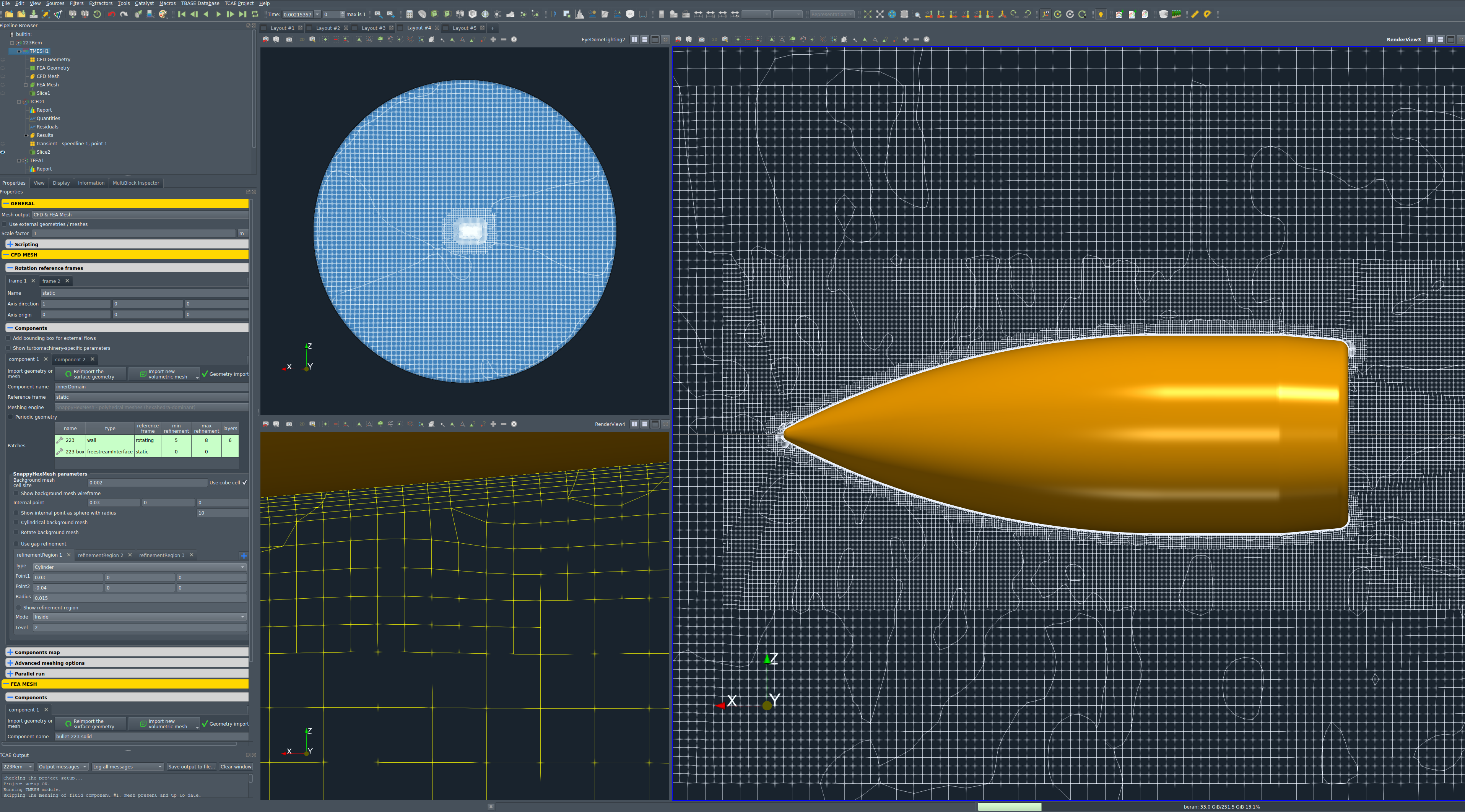

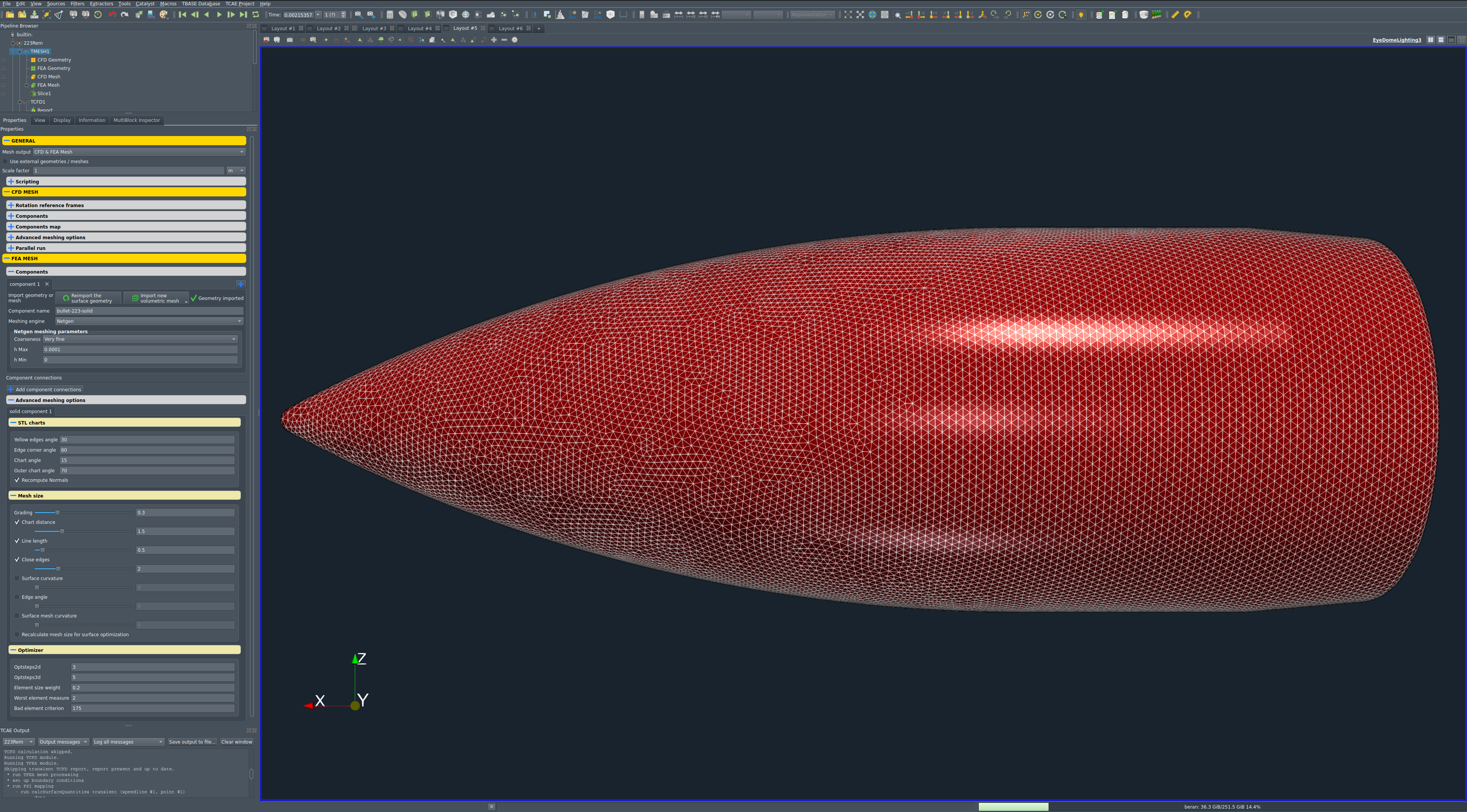

Bullet .223 Rem - CFD Preprocessing

In general, for CFD simulation it is best to split the geometrical model into several waterproof components because of rotation (some parts could be rotating and others not). Each component itself has to be waterproof and consists of a few or multiple STL surfaces. It is smart to split each component into multiple surfaces (more is better) because it opens a broader range of meshing options, simulation methods (mesh refinements, manipulation, boundary conditions, evaluation of results on model-specific parts, …), and postprocessing.

The principle is always the same: the 3D surface model has to be created; all the tiny, irrelevant, and problematic model parts must be removed, and all the holes must be sealed up (a watertight surface model is required). This centrifugal compressor CAD model is reasonably simple. The final surface model in the STL format is created as input for the meshing phase. This preprocessing phase of the workflow is extremely important because it determines the simulation potential and limits the CFD results.

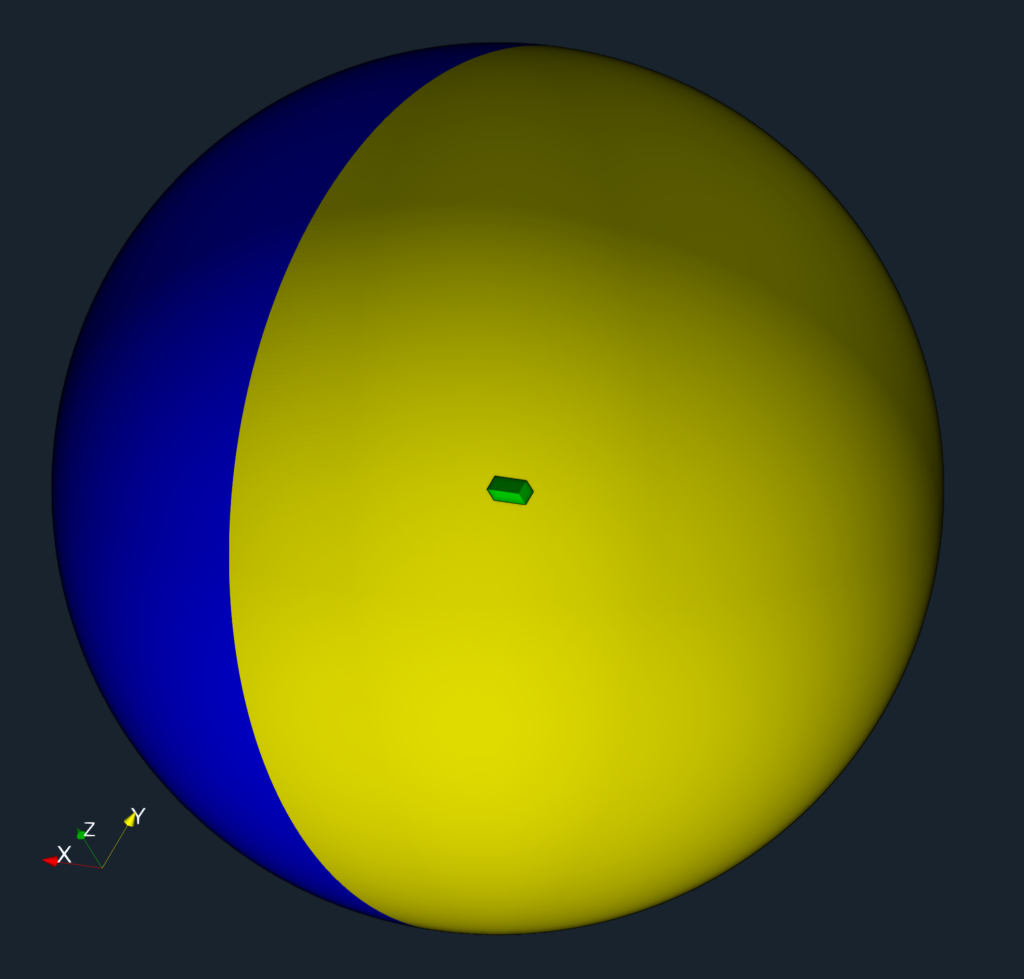

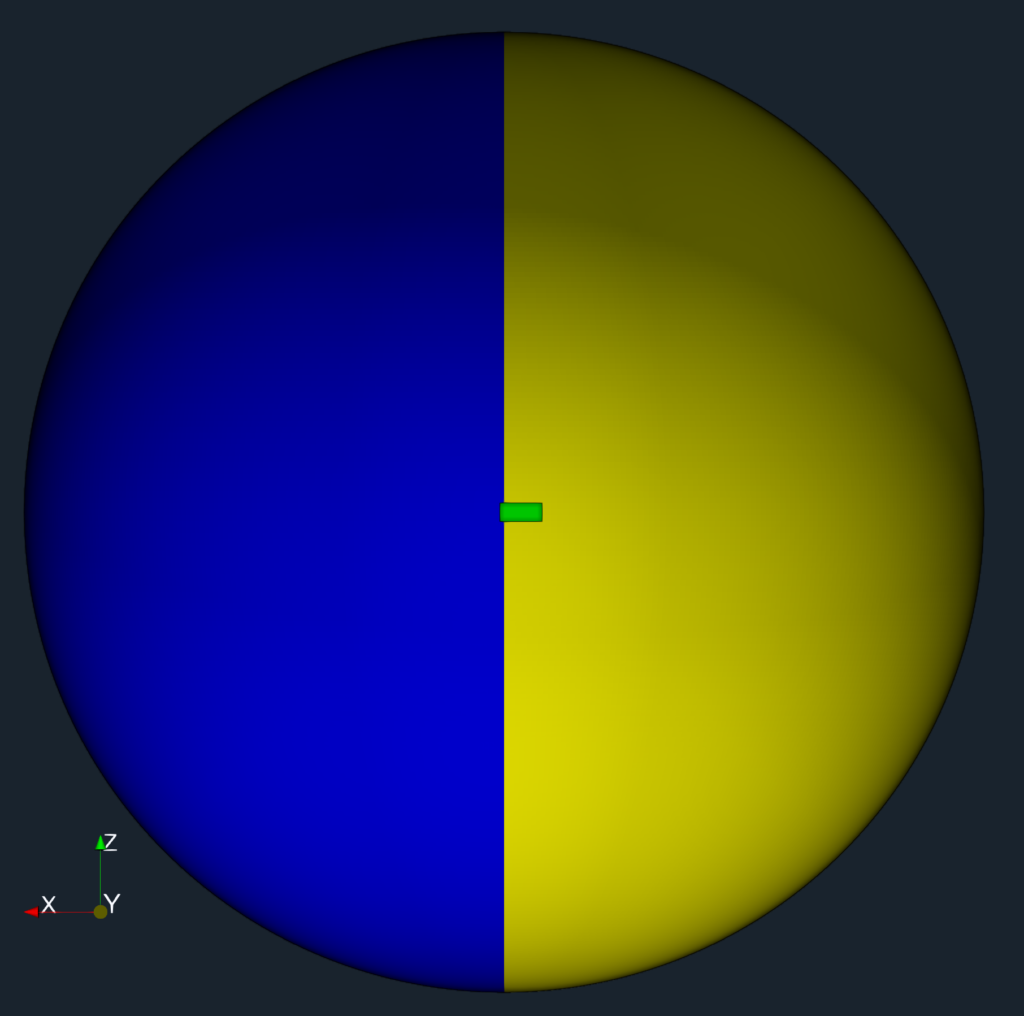

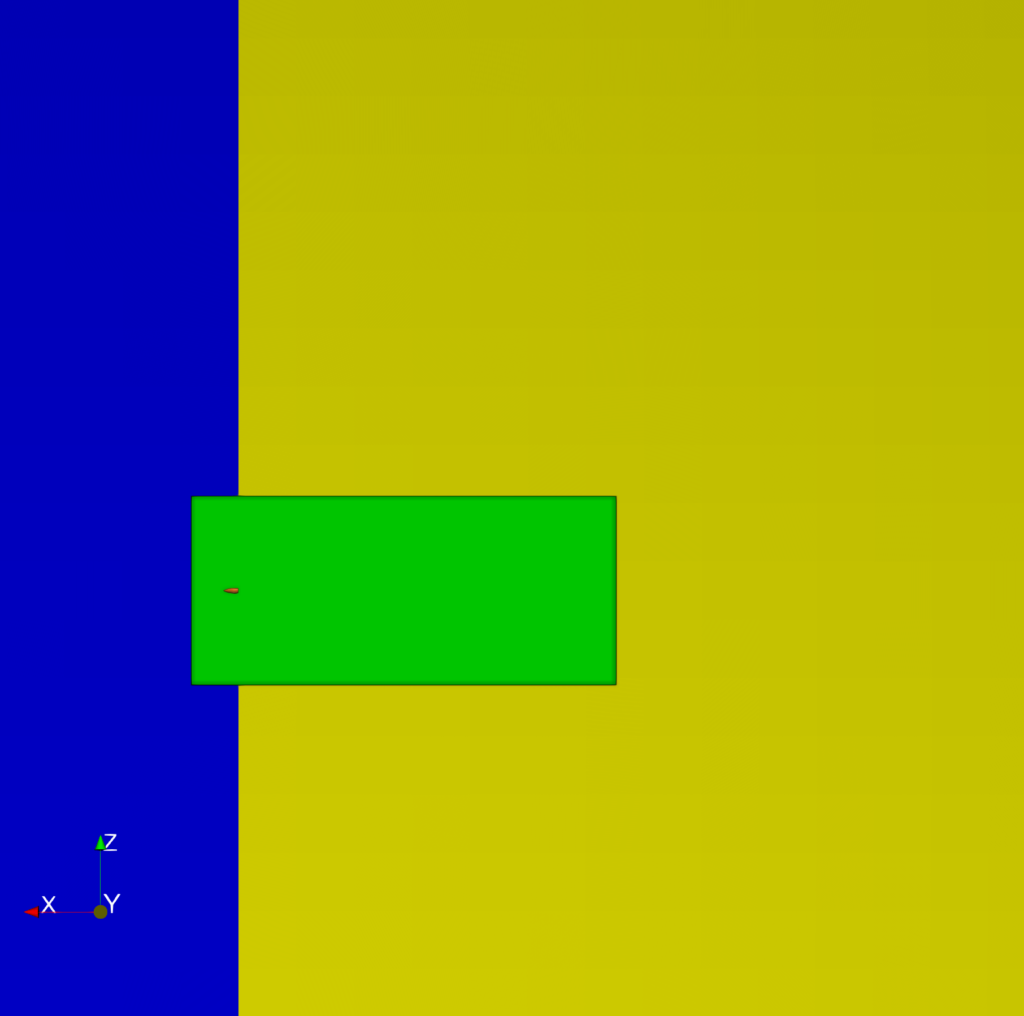

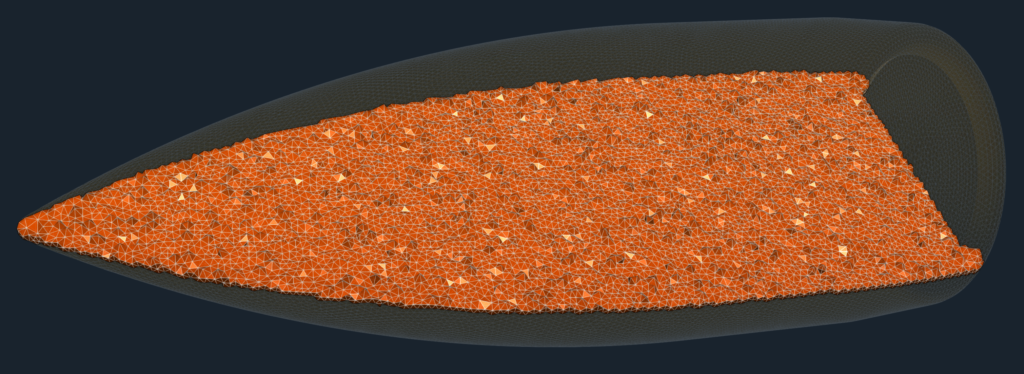

In external aerodynamics (cases with open boundaries) it’s useful to split the model into a large outer region with a relatively large mesh cells – and an inner region where the mesh can be much finer.

In this external aerodynamics case, the outer domain (region) is created with two hemispheres. The inner domain is a box which includes the examined object (bullet .223 Rem).

The surface model data in .stl file format together with physical inputs are loaded in TCFD. Another option would be loading an external mesh in OpenFOAM mesh format or loading an MSH mesh format (Fluent mesh format), or CGNS mesh format. This CFD methodology employs a multi-component approach, which means the model is split into a certain number of components. In TCFD each region can have its own mesh and individual meshes communicate via interfaces.

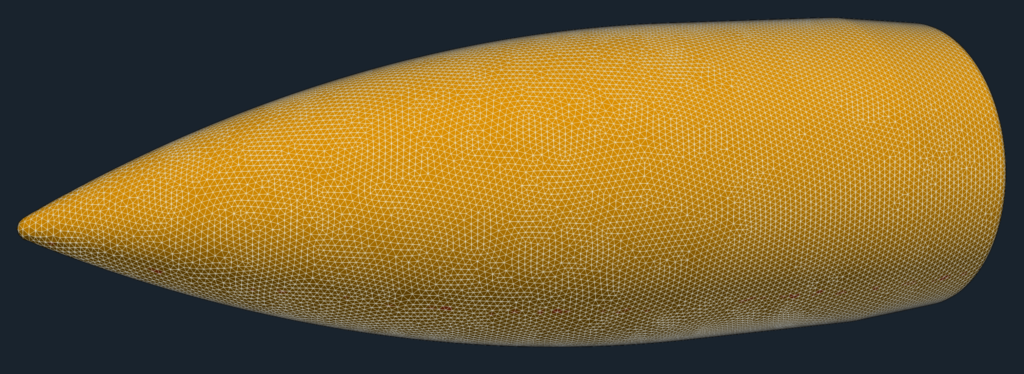

Bullet .223 Rem - FEA Preprocessing

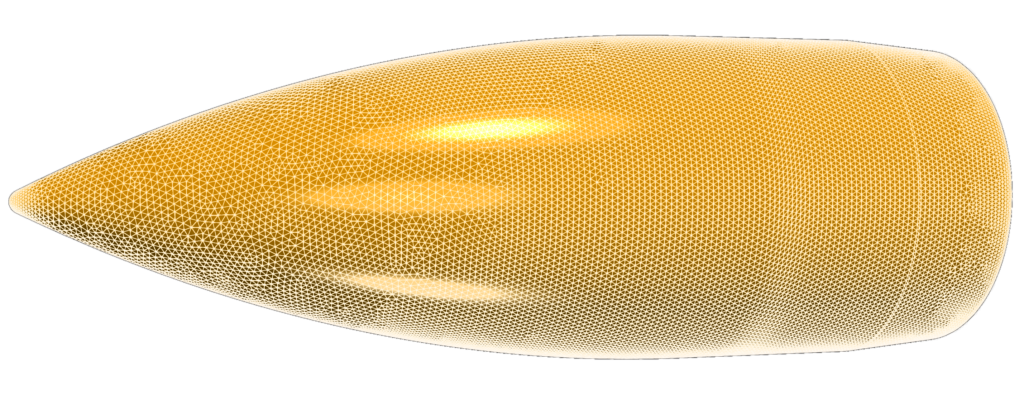

For FEA preprocessing, the rules are similar to CFD preprocessing and cleaning. It is best to create a simple, single, waterproof STL surface of the solid. After that, the model is ready for meshing with the TMESH module using NetGen or Gmsh open-source application. Alternatively, the FEA volume mesh can be loaded externally in Abaqus file format. In this particular study, the bullet body is investigated and the mesh is created in TMESH with NetGen.

IMPORTANT NOTICE ON PREPROCESSING

The surface of the simulation-ready model has to be clean, simple enough but not simpler! The principles are always the same: the watertight surface model has to be created; all the tiny, irrelevant, and problematic model parts must be removed, and all the holes must be sealed up (the watertight surface model is required). The preprocessing phase is an extremely important part of each simulation workflow. It sets up all the simulation potential and limitations. It should never be underestimated. Mistakes or poor quality engineering in the preprocessing phase can be hardly compensated later in the simulation phase and postprocessing phase. For more details, see the TCAE documentation.

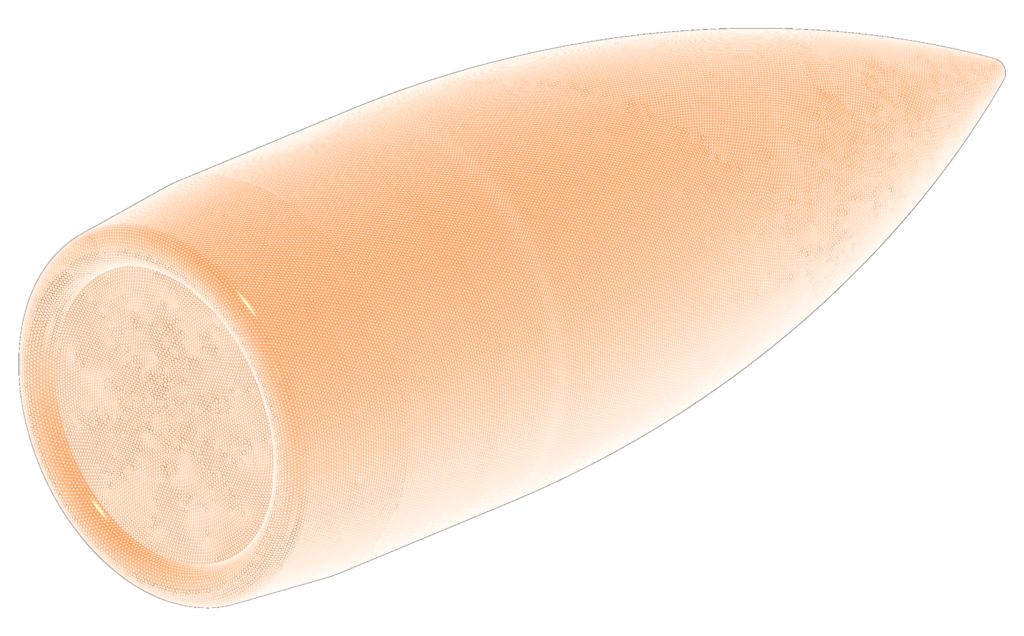

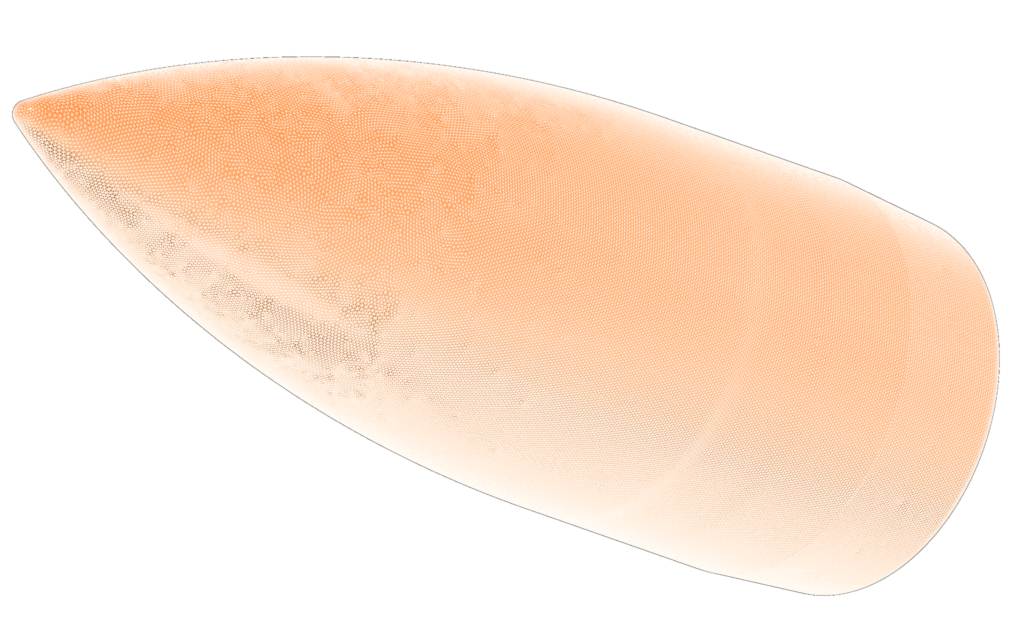

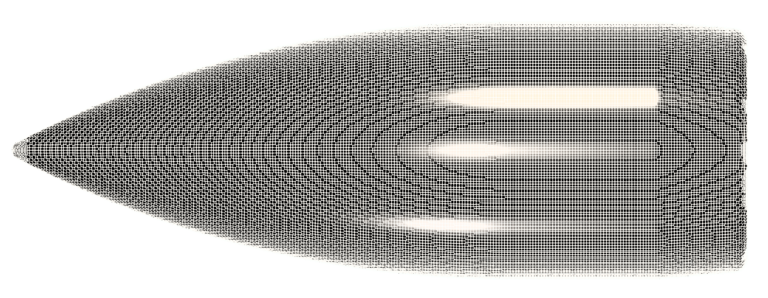

Bullet .223 Rem - CFD Meshing

The computational mesh for CFD is created in an automated software module TMESH, using the snappyHexMesh open-source application. All the mesh settings are done in the TCAE GUI.

For each model component, a cartesian block mesh is created (box around the model), as an initial background mesh, that is further refined along with the simulated object. Basic mesh cell size is a cube defined with the keyword “background mesh size”.

The mesh is gradually refined to the model wall. The mesh refinement levels can be easily changed, to obtain the coarser or finer mesh, to better handle the mesh size. Inflation layers can be easily handled if needed. The final mesh statistics are following:

Number of cells: Axial inlet: 207547; impeller: 4217674; vaneless: 331988; diffuser: 607453; EGV : 475608; Total cells: 5840270. Including 8 inflation layers on walls.

Bullet .223 Rem - FEA Meshing

The computational mesh for FEA is created in an automated software module TMESH, using the NetGen open-source application. All the mesh settings are done in the TCAE GUI.

The closed STL model has been meshed with just a little effort because there are just a few parameters to set. The most important parameters for FEA meshing are “h Max” and “h Min” which mean the maximal and minimal mesh edge in meters. The mesh is created with an automated algorithm.

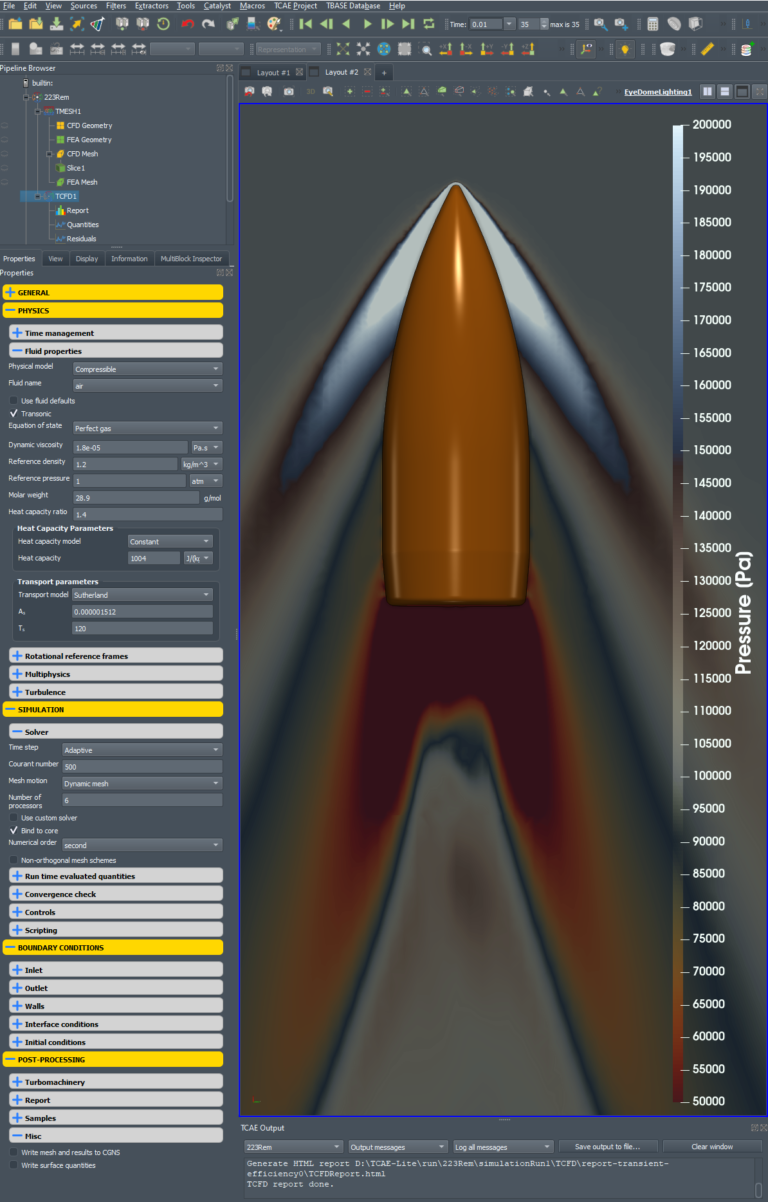

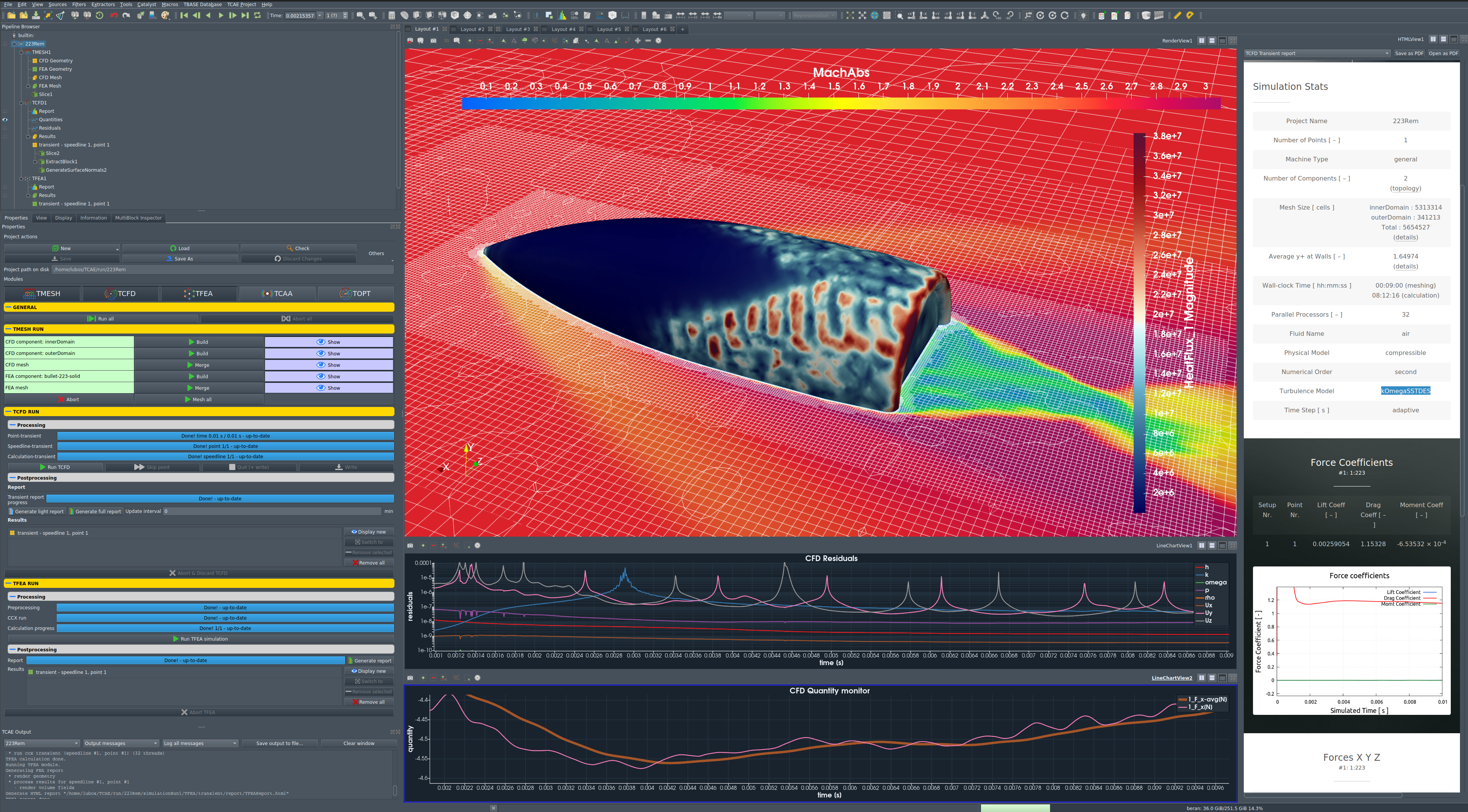

Bullet .223 Rem - CFD Simulation Setup

The CFD simulation is managed with TCAE software module TCFD. Complete CFD simulation setup and run is done in the TCFD GUI in ParaView. TCFD uses solvers based on OpenFOAM open-source software.

The bullet is rotating at a relatively high speed. For a .223 Remington bullet with a 1:7 twist barrel and 900 m/s muzzle velocity, the rotational speed is approximately 303000 RPM.

- Simulation type: general

- Time management: transient

- Physical model: Compressible

- Number of components: 2 [-]

- Wall roughness: none

- Bullet rotation speed: 303360 [RPM]

- Outlet: variable static pressure [m2/s2]

- Turbulence: DES

- Turbulence model: k-omega SST

- Shear Thinnig model: Newtonian

- Wall treatment: smart wall functions

- Turbulence intensity: 5%

- Speedlines: 1 [-]

- Simulation points: 1 [-]

- Fluid: Air

- Reference pressure: 1 [atm]

- Dynamic viscosity: 2.144 × 10E-5 [Pa⋅s]

- Reference density: 1.2 [kg/m3]

- CFD CPU Time for T=0.01s: 272 core.hours

- Blade-To-Blade: off

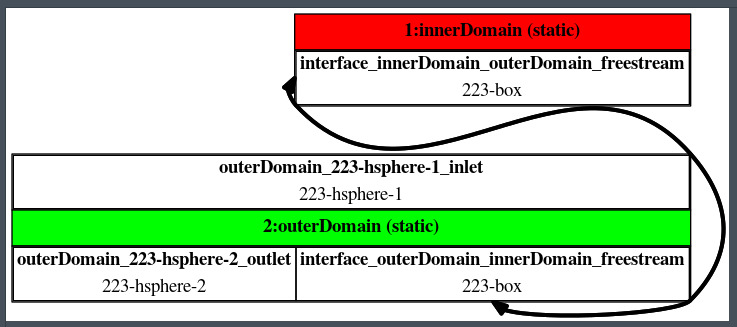

Every project simulated in TCFD has its component graph. The component graph is a simple scheme that shows how the components are organized. The flow model topology, the inlet, the outlet, and how the components are connected via interfaces. The component graph is shown below.

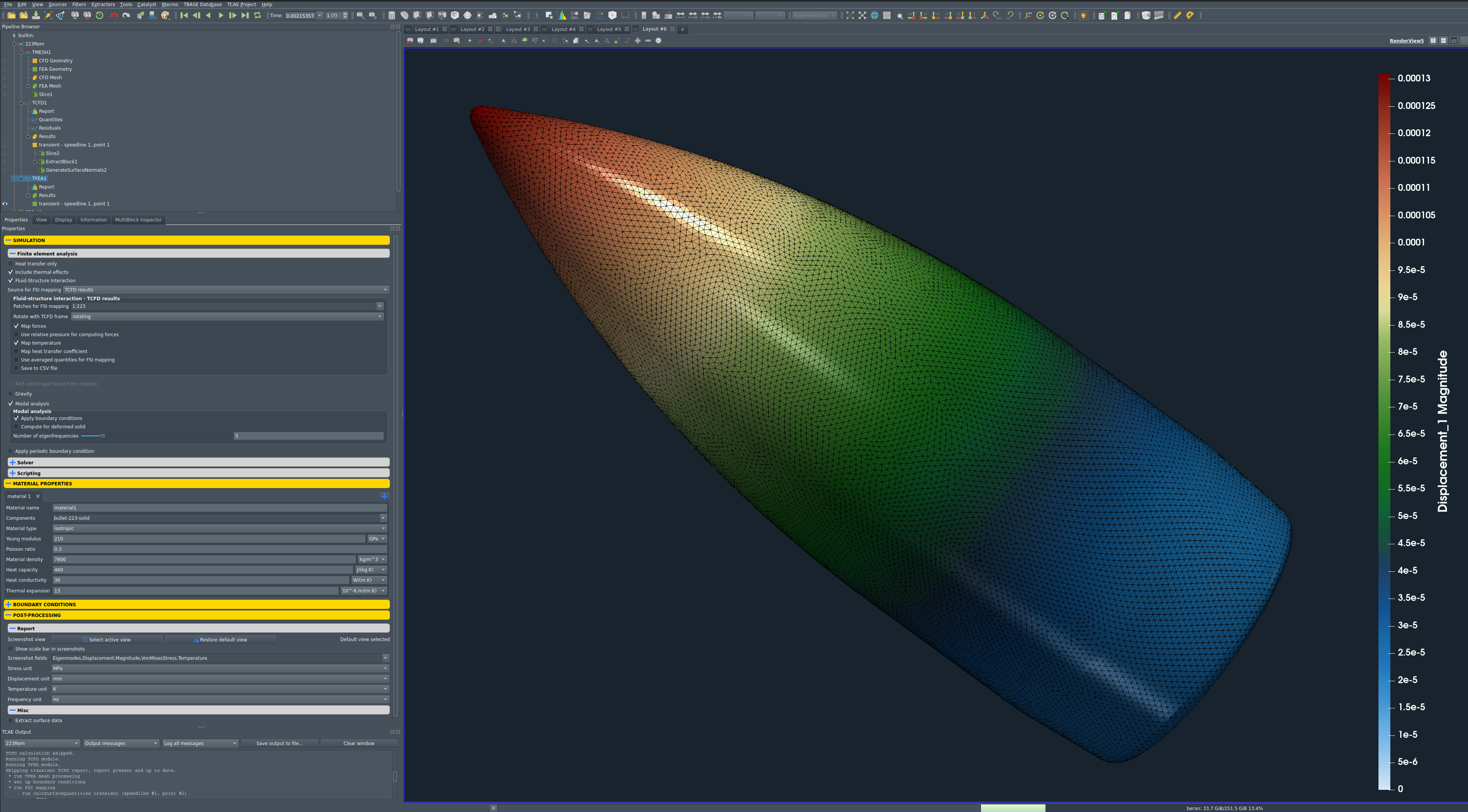

Bullet .223 Rem - FEA Simulation Setup

The FEA simulation is managed with TCAE software module TFEA. Complete FEA simulation setup and run are done in the TFEA GUI in ParaView. TFEA is based on the Calculix open-source application.

- Impeller material: Lead

- Material structure: isotropic

- Young modulus: 16 GPa

- Material density: 11340 kg/m3

- FSI source: TCFD [-]

- Poisson ratio: 0.44

- Fixed area: bottom center ~ 1 [mm]

- Finite element order: second

- FEA CPU Time: 0.1 core.hours/point

- Speed of rotation: 303360 [RPM]

Bullet .223 Rem - TCAE Simulation Run

The TCAE simulation run is completely automated. The whole workflow can be run by a single click in the GUI, or the whole process can be run in batch mode on a background. Modules used in this particular project are TCAD, TMESH, TCFD, and TFEA. The simulation is executed in the steady-state mode, for four speed-lines with total 44 points as they were measured in the experiment [1].

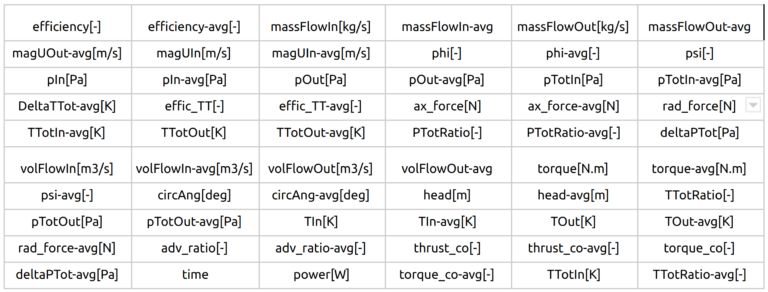

TCFD includes a built-in post-processing module that automatically evaluates all the required quantities, such as efficiency, torque, forces, force coefficients, flow rates, pressure, velocity, and much more. All these quantities are evaluated throughout the simulation run, and all the important data is summarized in an HTML report, which can be updated anytime during the simulation, for every run.

All the simulation data are also saved in tabulated .csv files for further evaluation. TCFD is capable of writing the results down at any time during the simulation. The convergence of basic quantities and integral quantities are monitored still during the simulation run. The geometry was created one-time using TCAD in the preprocessing phase. First, the TMESH is executed to create the volume meshes for CFD & FEA. Then the CFD simulation is executed and evaluated. After that, in the FSI step, the pressure field is integrated to create the force field which is prescribed as a load for the FEA simulation. Finally, the FEA simulation is executed and evaluated.

Bullet .223 Rem - Postprocessing - Integral Results

The integral results and simulation statistics are evaluated automatically for every simulation run. Every simulation run in TCAE has its own unique simulation report. The integral results both for CFD and FEA are written down in the corresponding HTML or PDF reports.

All the relevant integral quantities are evaluated, sorted, and stored in the corresponding CSV files and are ready for further usage. Following integral quantities are evaluated every time step.

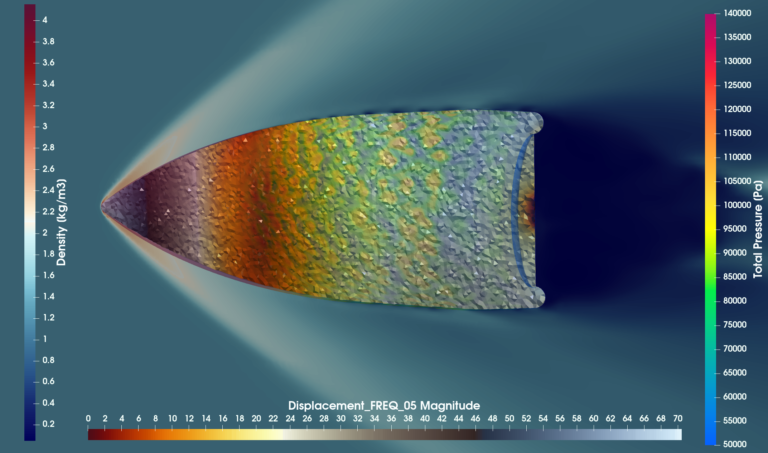

Bullet .223 Rem - Postprocessing - Volume Fields

While all the integral results are stored in the CSV files and are available for further postprocessing, the volume fields are post-processed in the open-source visualization tool ParaView. ParaView provides a wide range of tools and methods for CFD & FEA postprocessing and results evaluation. There are available countless useful filters and sources, for example, Calculator, Contour, Clip, Slice, Threshold, Glyph (Vectors), Streamtraces (Streamlines), and many others.

CFD Volume Fields

Conclusion

- It has been shown how to make a comprehensive CFD & FEA analysis including FSI of the bullet .223 Rem in a single automated workflow.

- There remains a lot of space for tuning the CFD methodology, especially for the mesh resolution, turbulence modeling, and numerical schemes.

- TCAE showed to be a very effective tool for CFD, FEA, and FSI engineering simulations for all rotating machinery in general.

- This benchmark study was intentionally written in short not to overwhelm its readers with too many details.

- The original intention was to show the modern simulation workflow and its potential.

- All the technical details regarding CFD & FEA simulation are listed in the TCAE manual.

- The benchmark geometry and data are freely available for download on the CFDSUPPORT website https://www.cfdsupport.com.

- More information about TCAE can be found on the CFD SUPPORT website: https://www.cfdsupport.com/tcae.html

- Questions will be happily answered via email info@cfdsupport.com.

References

Download TCAE Tutorial - Bullet .223 Rem

File name: 223Rem-TCAE-Tutorial.zip

File size: 8 MB

Tutorial Features: CFD, FEA, FSI, TCAE, TMESH, TCFD, TFEA, SIMULATION, COMPRESSIBLE FLOW, DEFORMATION, DISPLACEMENT, STRESS, MODAL ANALYSIS, COMPRESSIBLE, TRANSIENT, DES KW, AUTOMATION, WORKFLOW, SNAPPYHEXMESH, NETGEN, RPM=303360, SUPERSONIC, EXTERNAL AERODYNAMICS