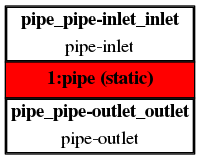

| Test Case Name |

Pipe-Tutorial |

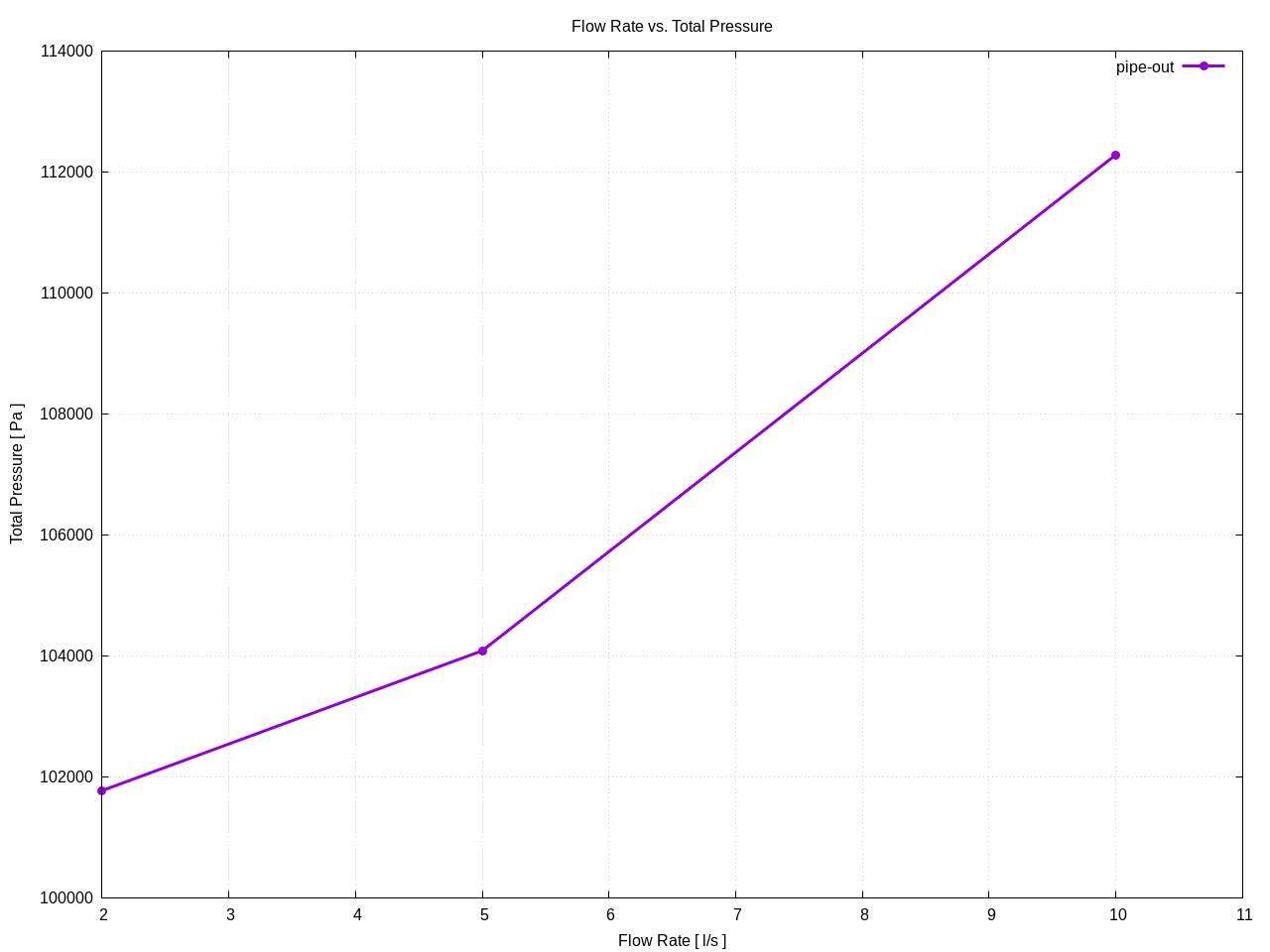

| Number of Points [ – ] |

3 |

| Machine Type |

stator |

| Rotation Speed [ RPM ] |

0 |

|

Number of Components [ – ] (topology) |

1 |

|

Mesh Size [ cells ] (details) |

pipe : 46618

Total : 46618 |

|

Mesh details [ mm ]:

| Component |

Property |

Min |

Max |

Avg |

| 1 |

cellOpenness |

N/A |

4.02035 × 10-16

|

N/A |

| 1 |

cellVolume |

3.68108 |

85.0800 |

N/A |

| 1 |

faceArea |

0.841881 |

29.2795 |

N/A |

| 1 |

aspectRatio |

N/A |

12.0671 |

N/A |

| 1 |

nonOrthogonality |

N/A |

60.5284 |

9.03920 |

| 1 |

skewness |

N/A |

0.628769 |

N/A |

| 1 |

edgeLength |

N/A |

N/A |

N/A |

| 1 |

concaveAngle |

N/A |

N/A |

N/A |

| 1 |

faceFlatness |

0.902295 |

N/A |

0.998018 |

| 1 |

cellDeterminant |

0.0207900 |

N/A |

4.27817 |

| 1 |

faceInterpolationWeight |

0.105846 |

N/A |

0.452039 |

| 1 |

faceVolumeRatio |

0.0864716 |

0.811523 |

N/A |

| 1 |

Warnings: |

115 faces with low quality or negative volume decomposition tets

160 concave cells

|

|

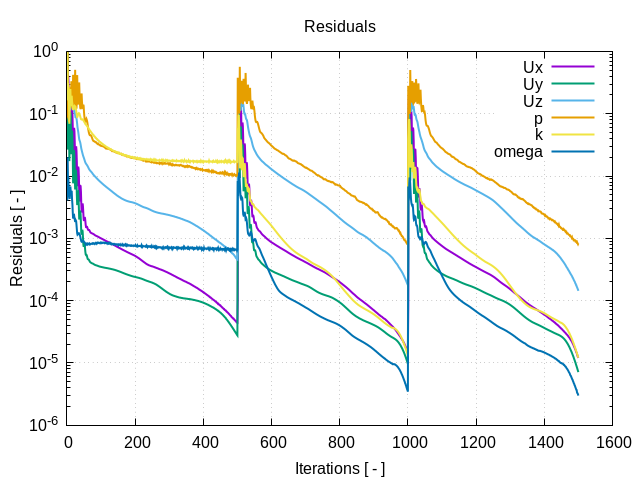

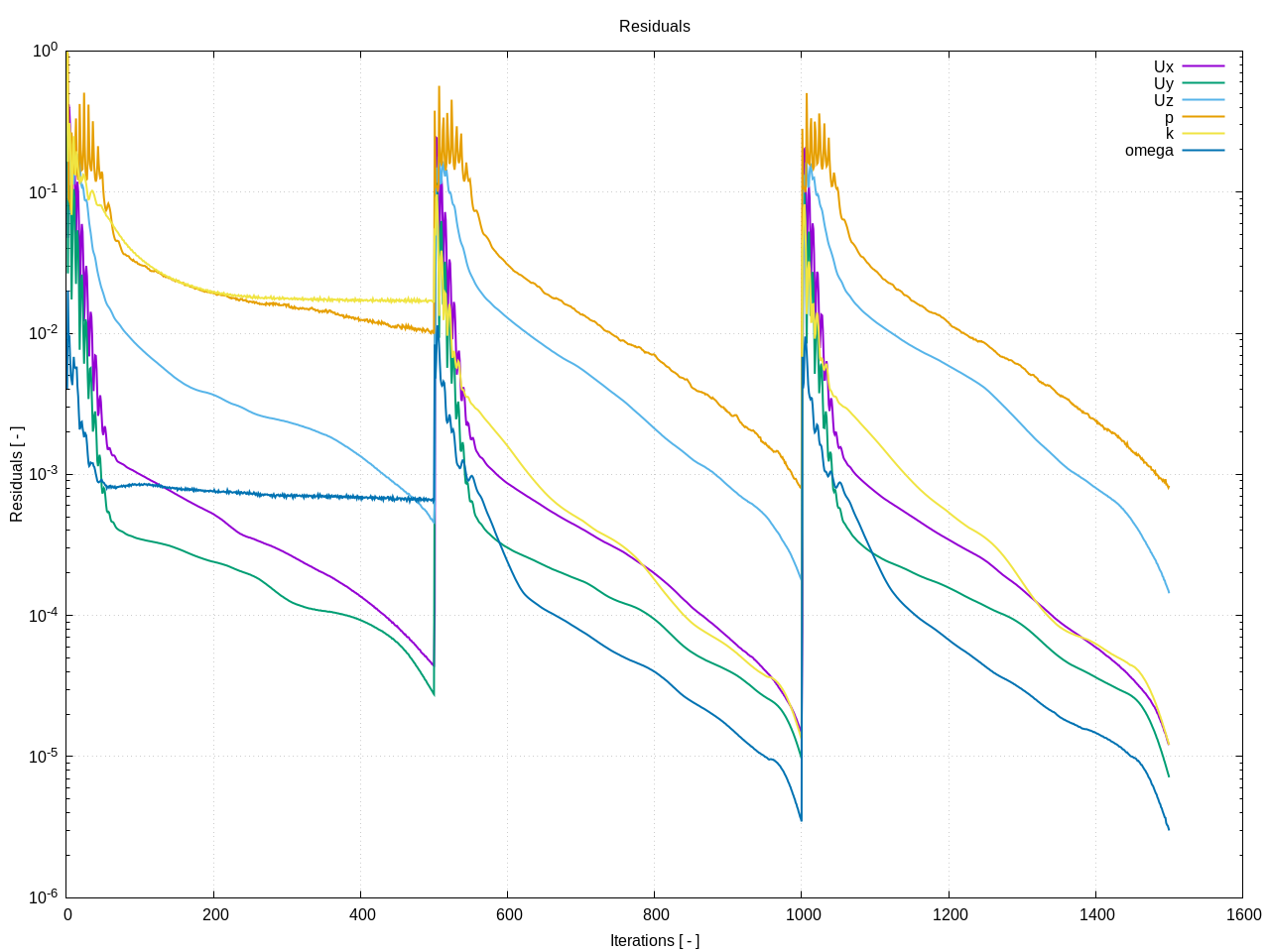

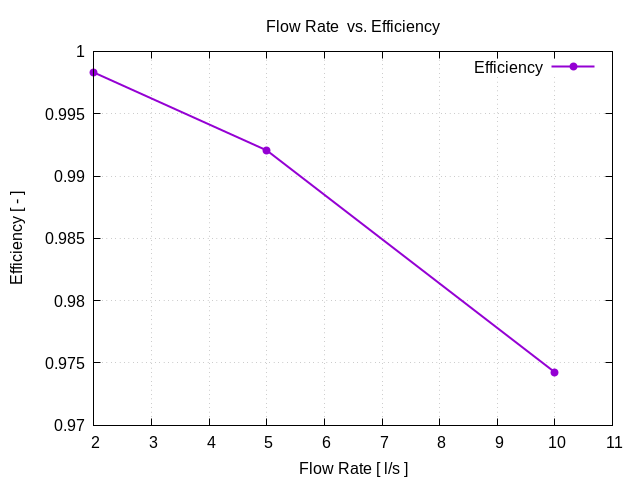

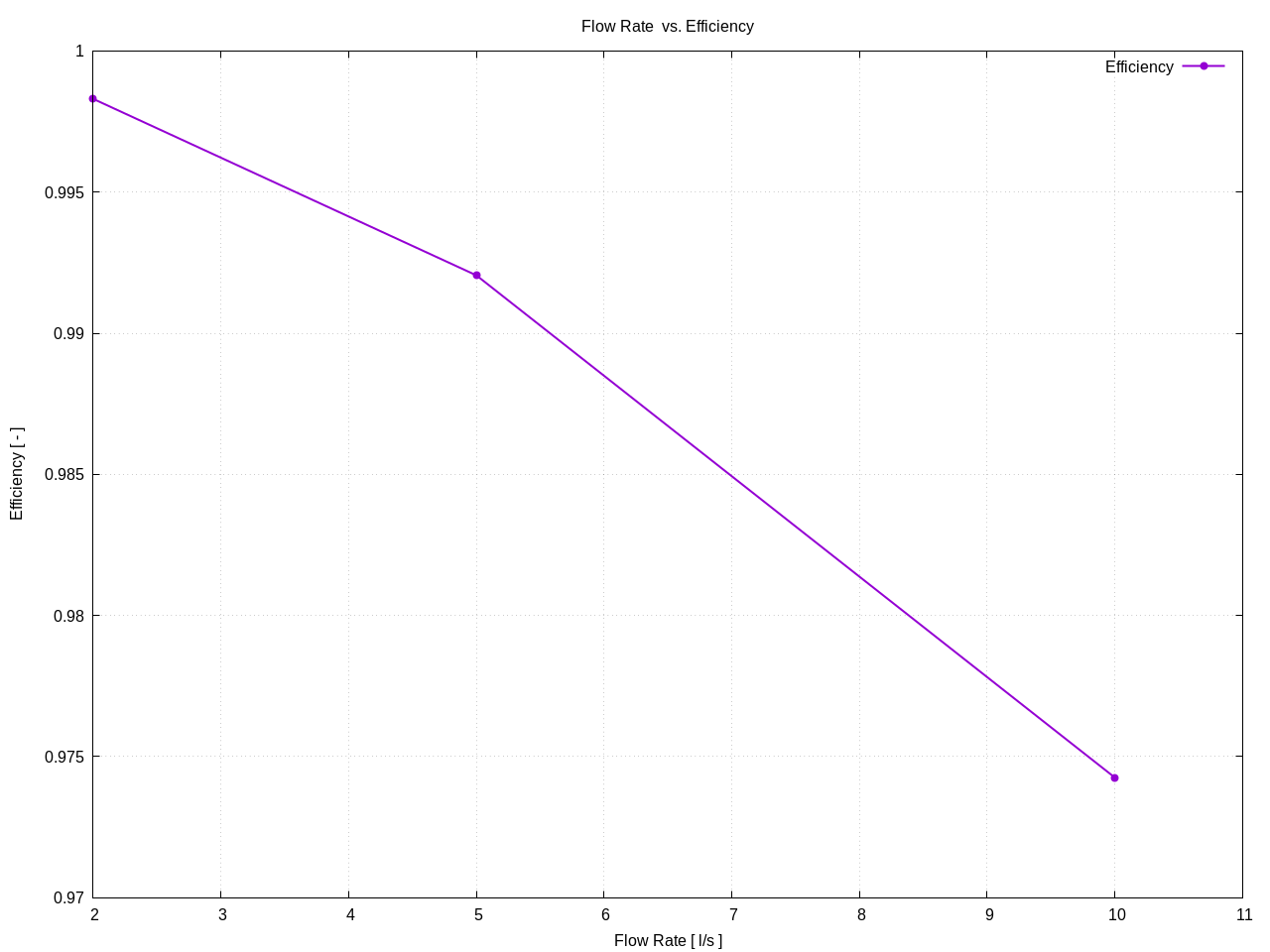

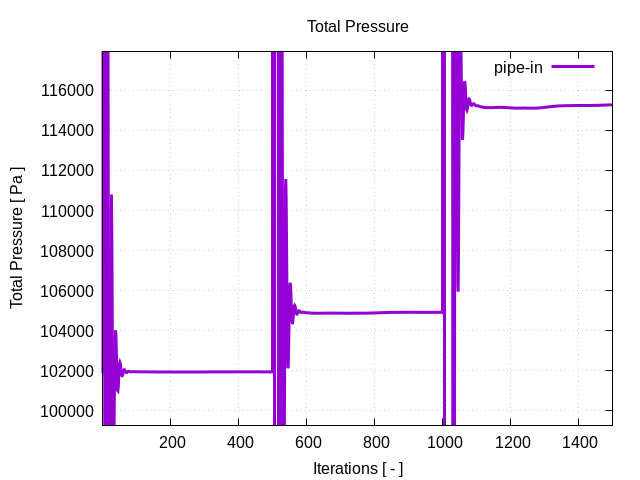

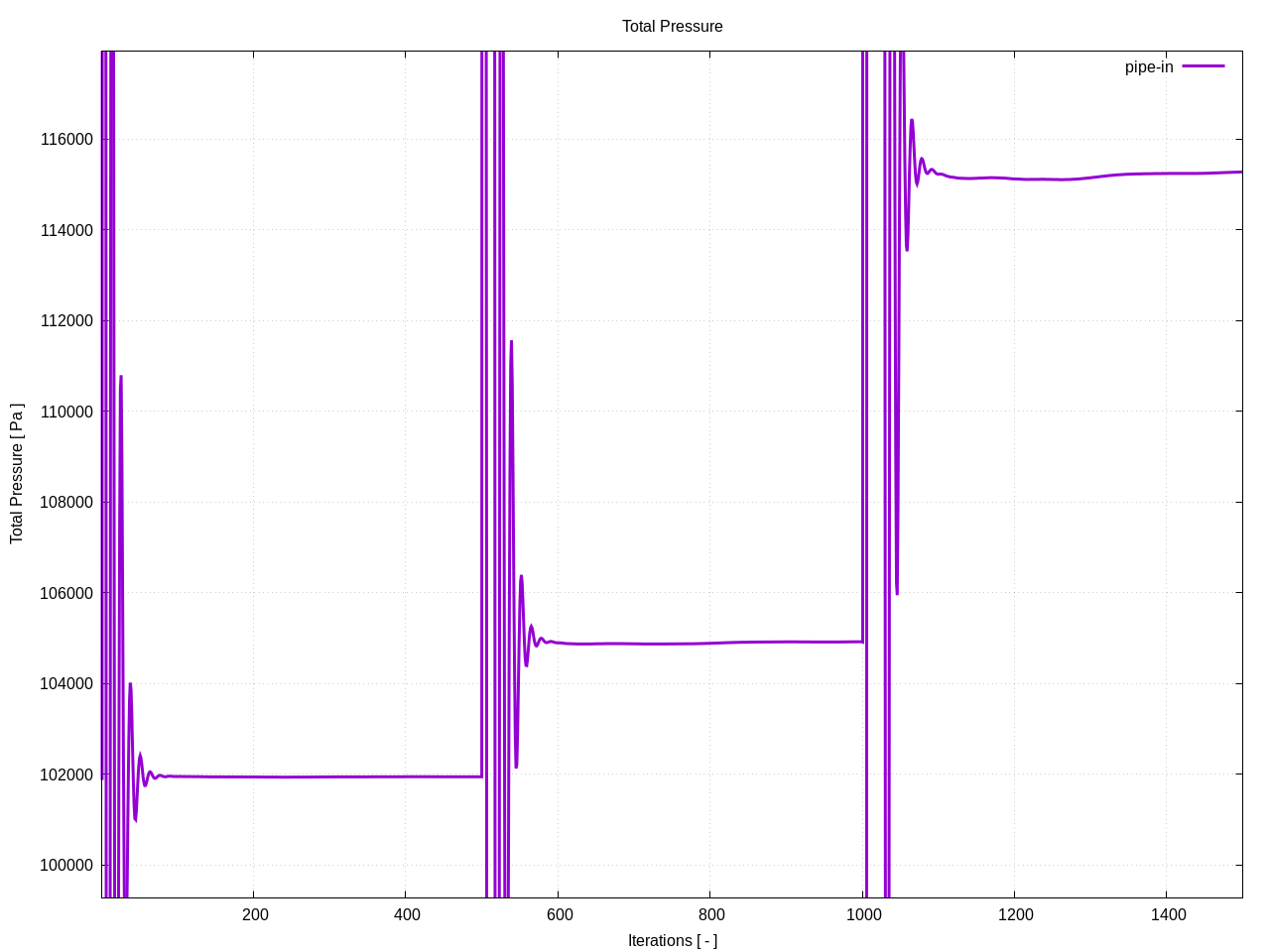

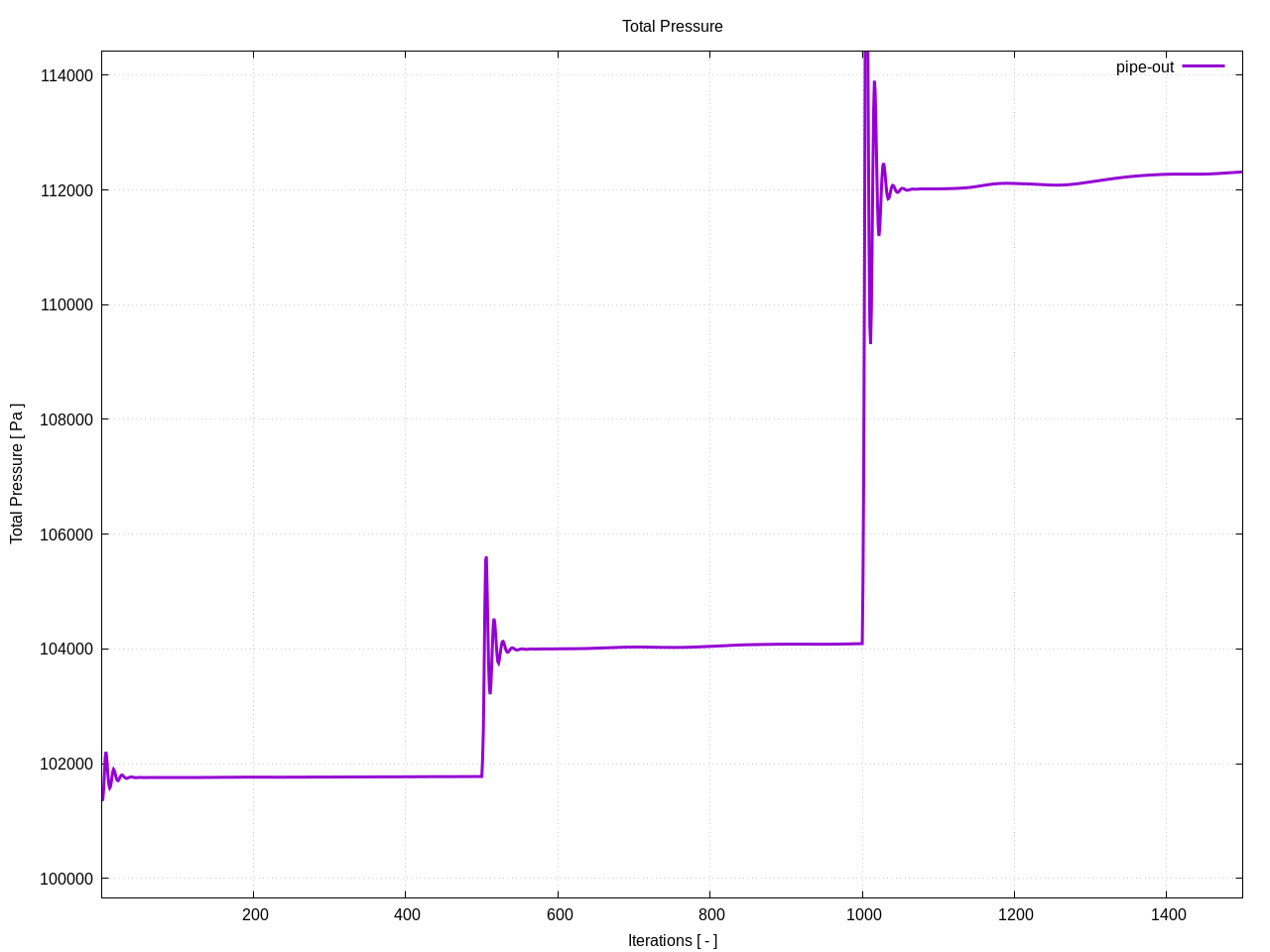

| Simulation score [ – ] |

details |

|

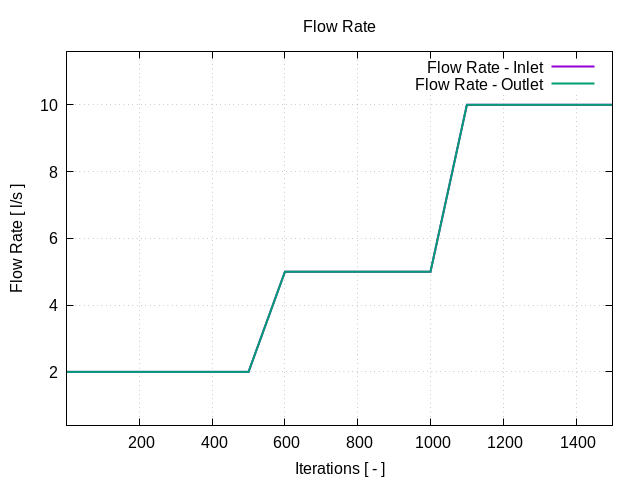

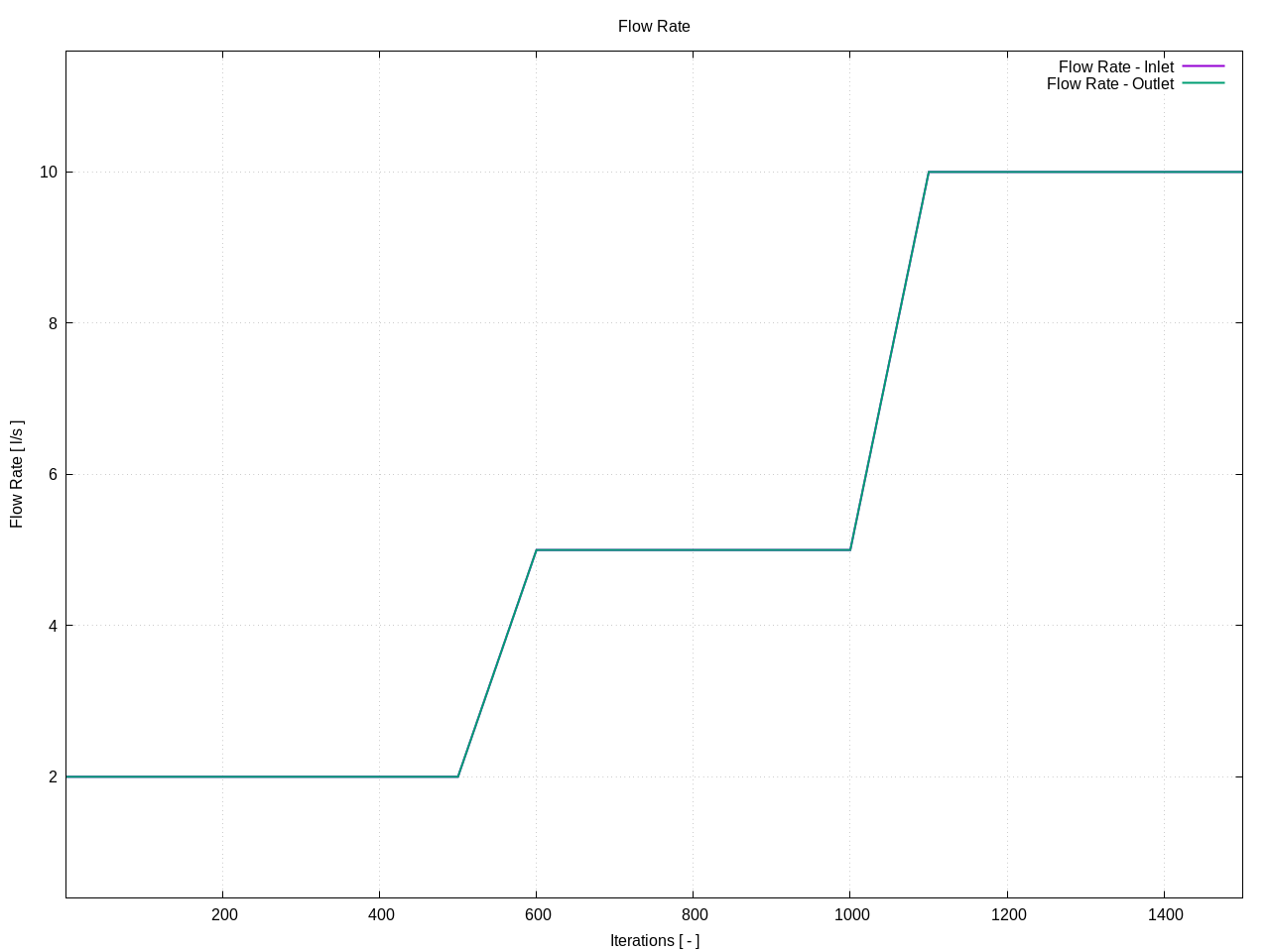

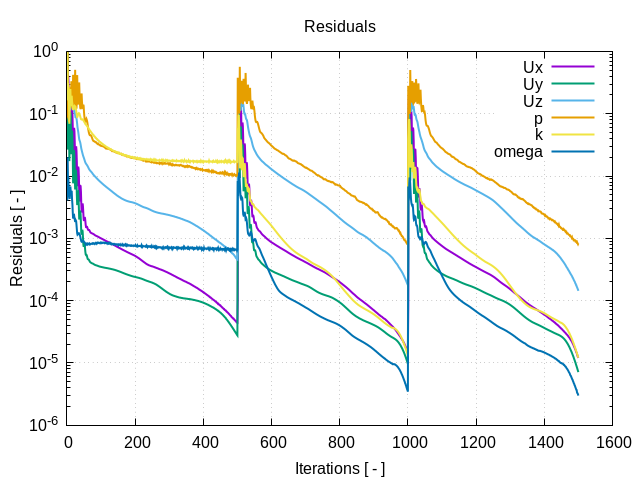

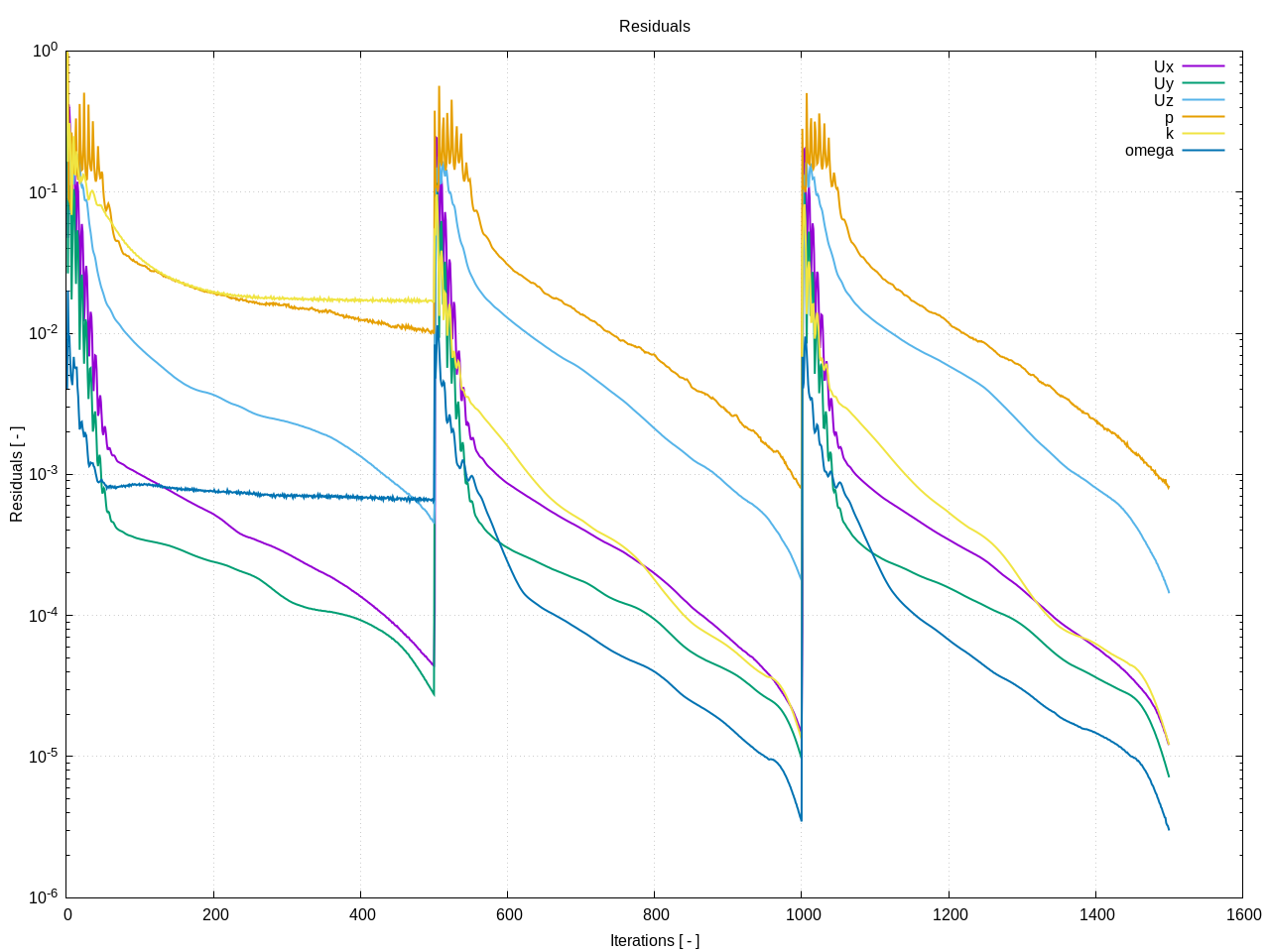

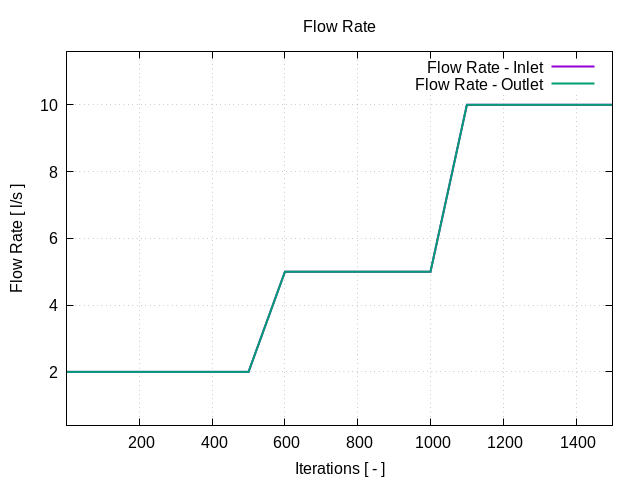

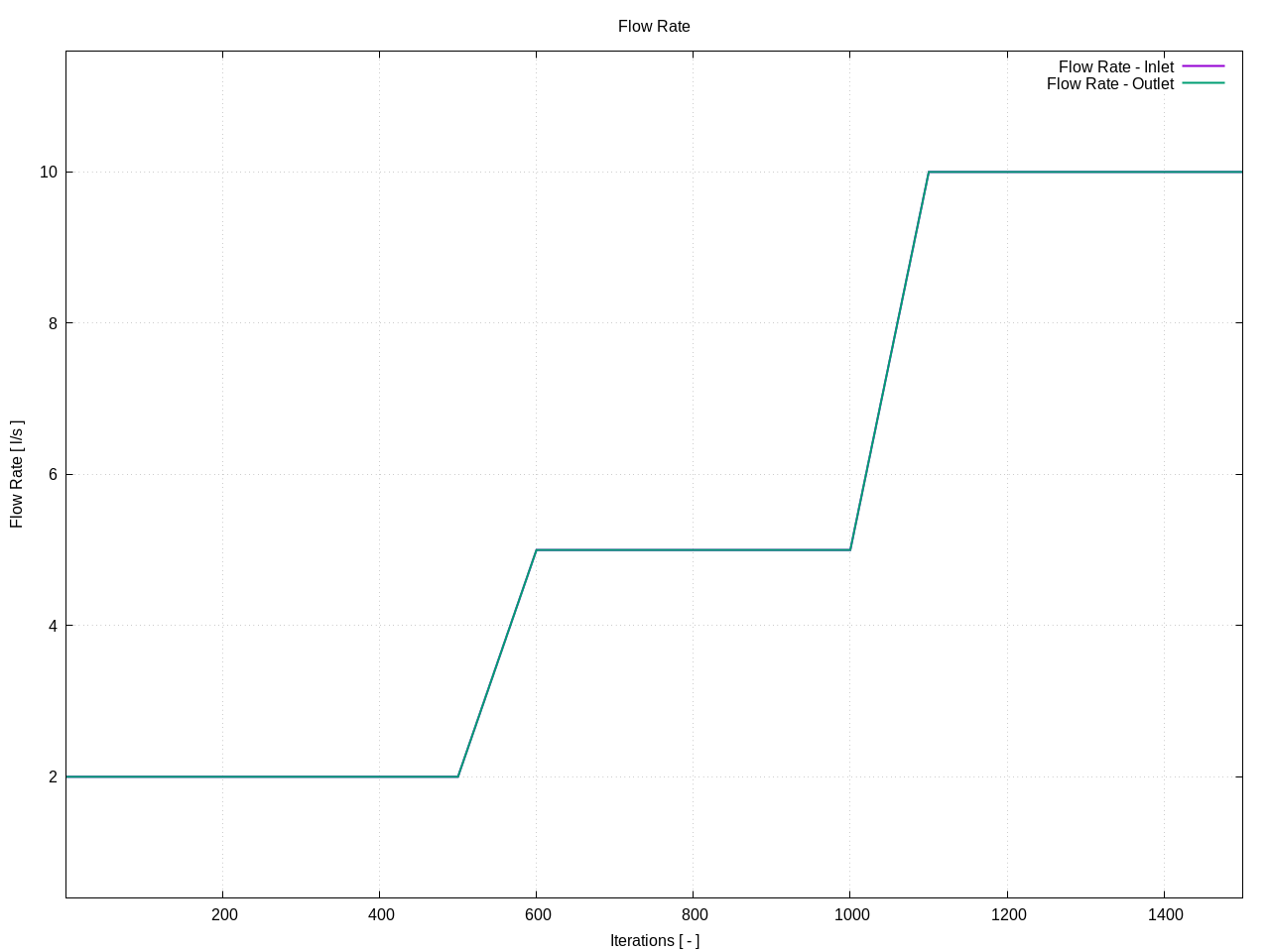

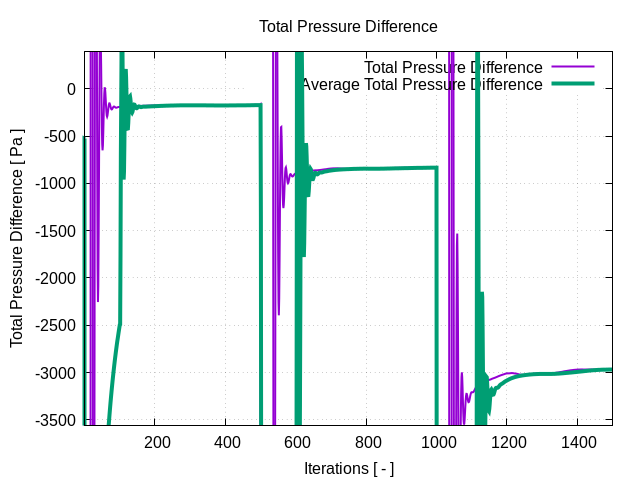

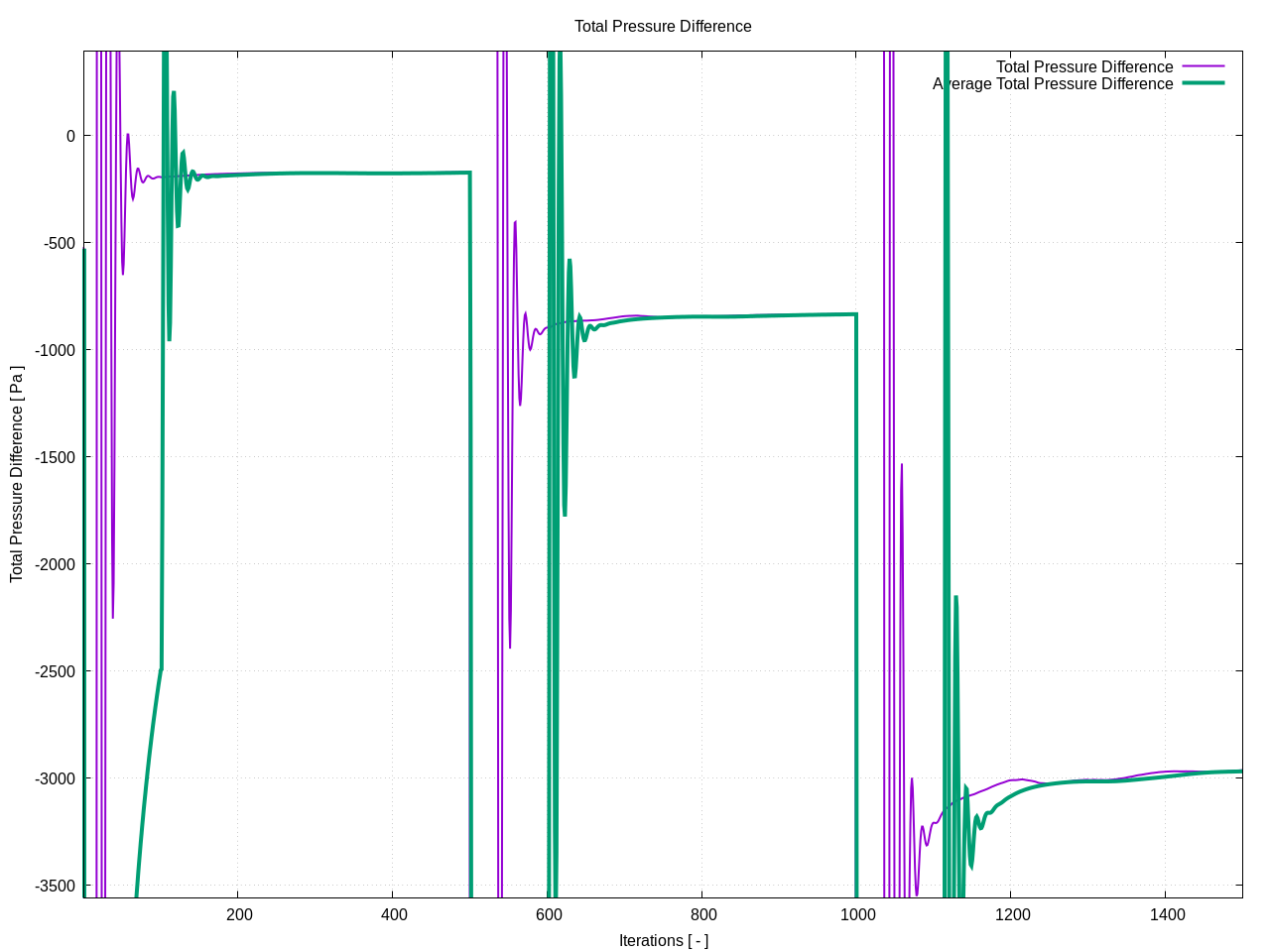

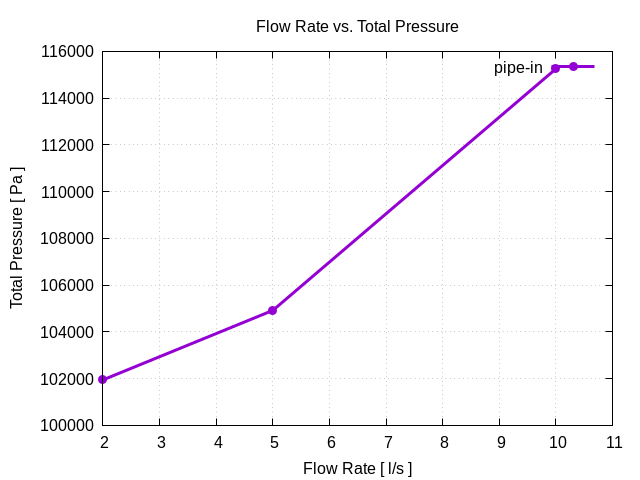

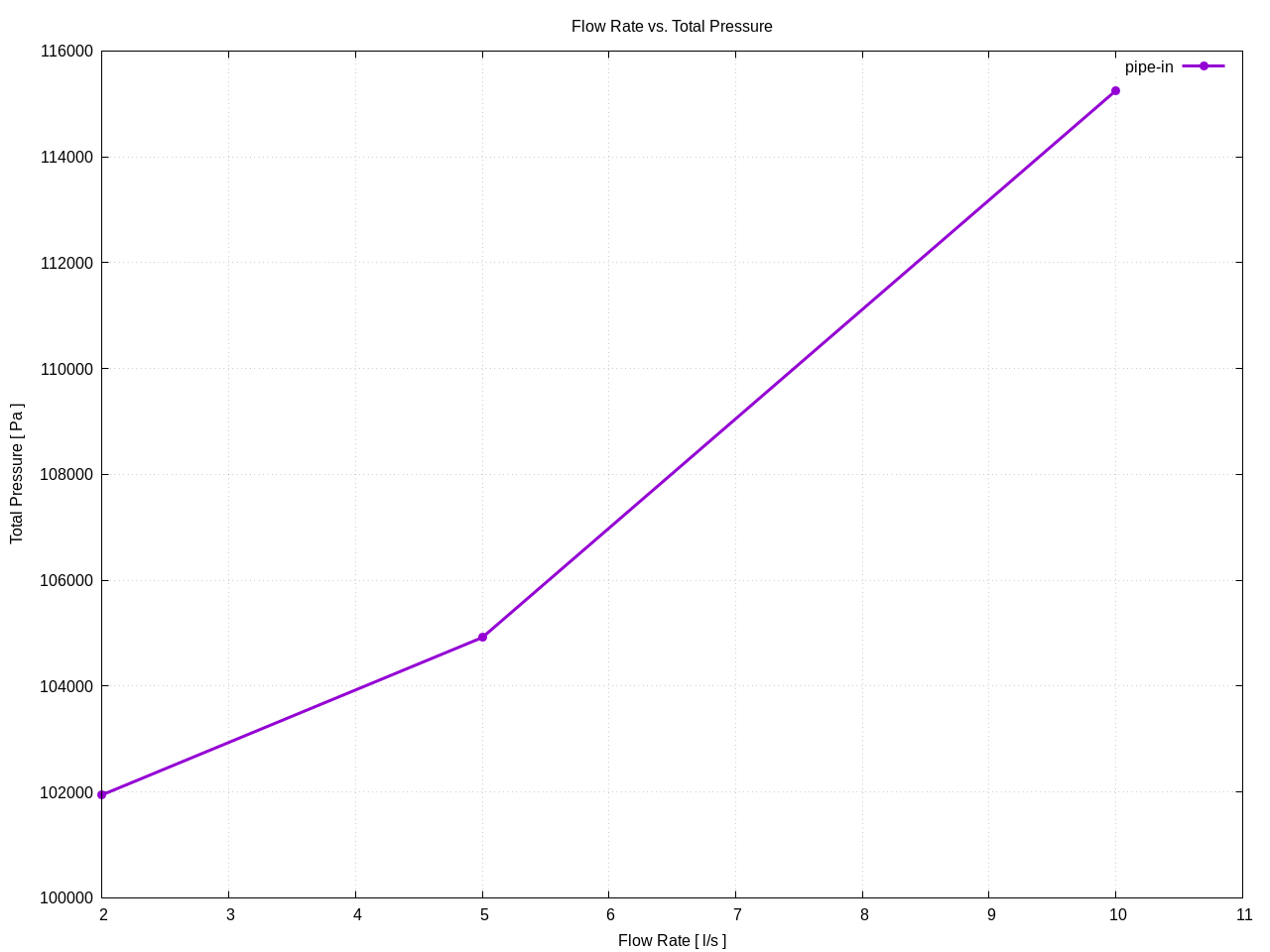

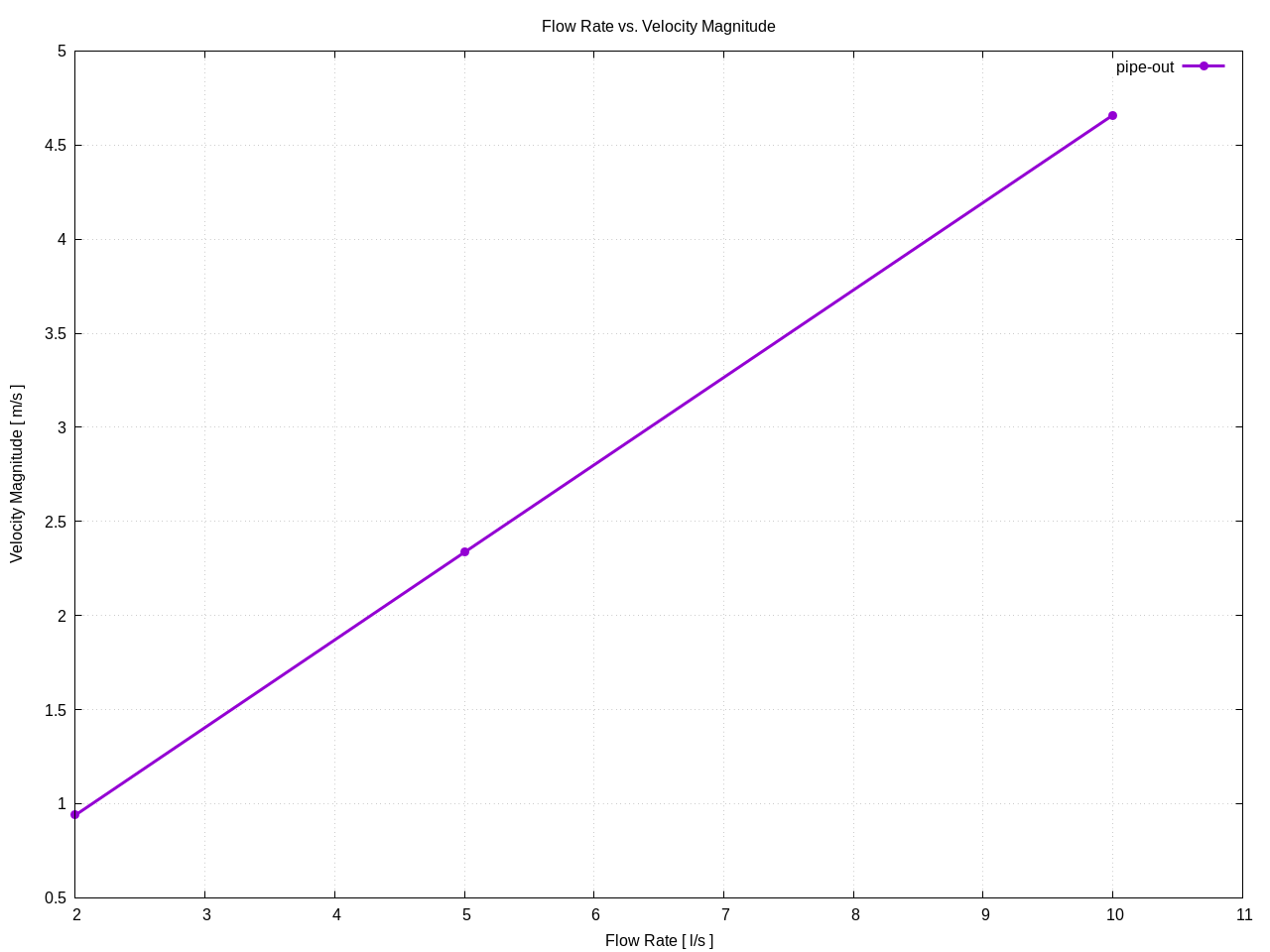

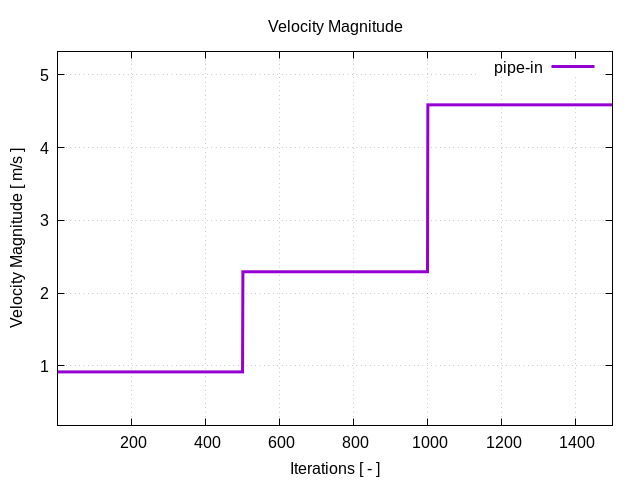

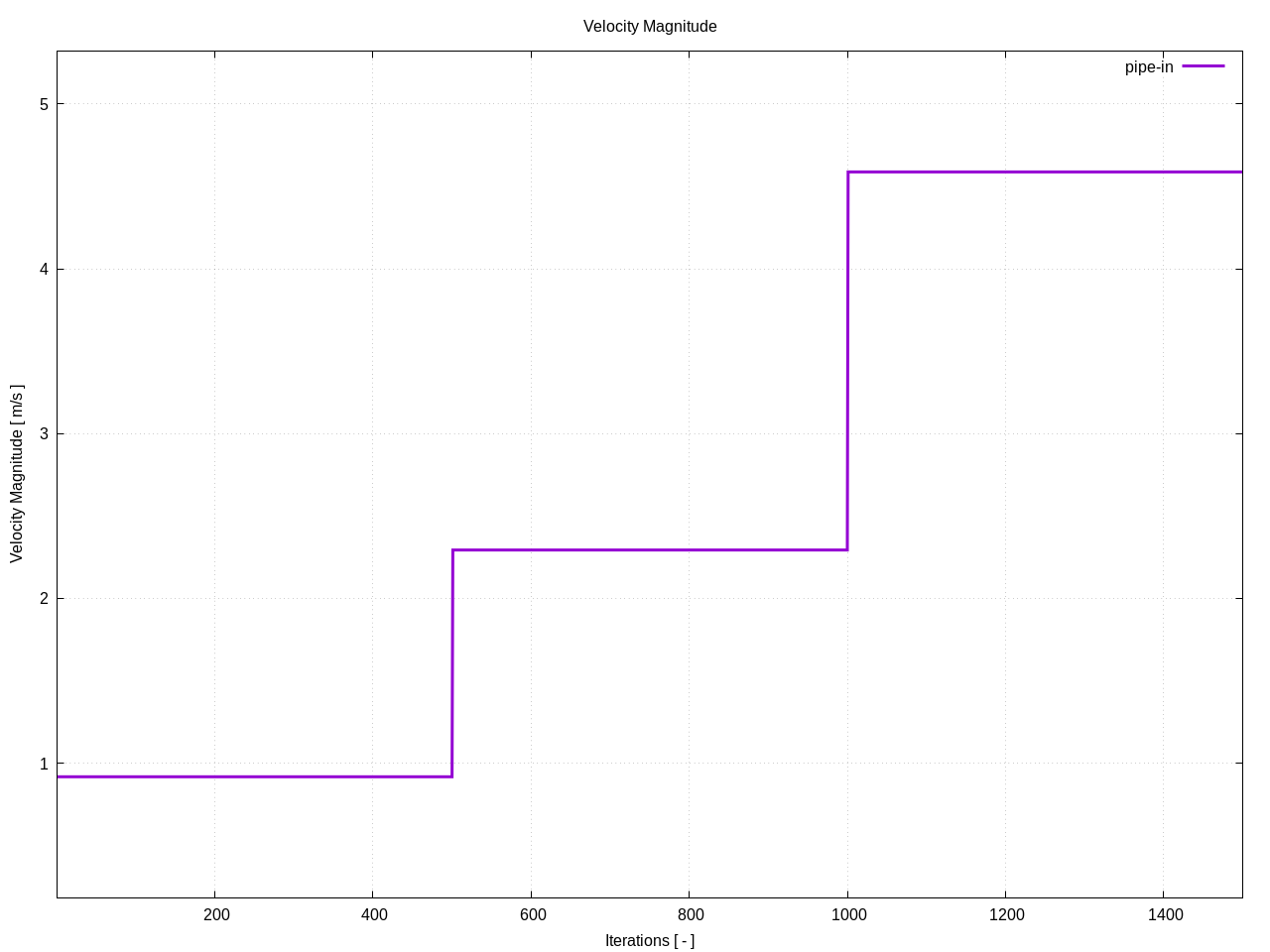

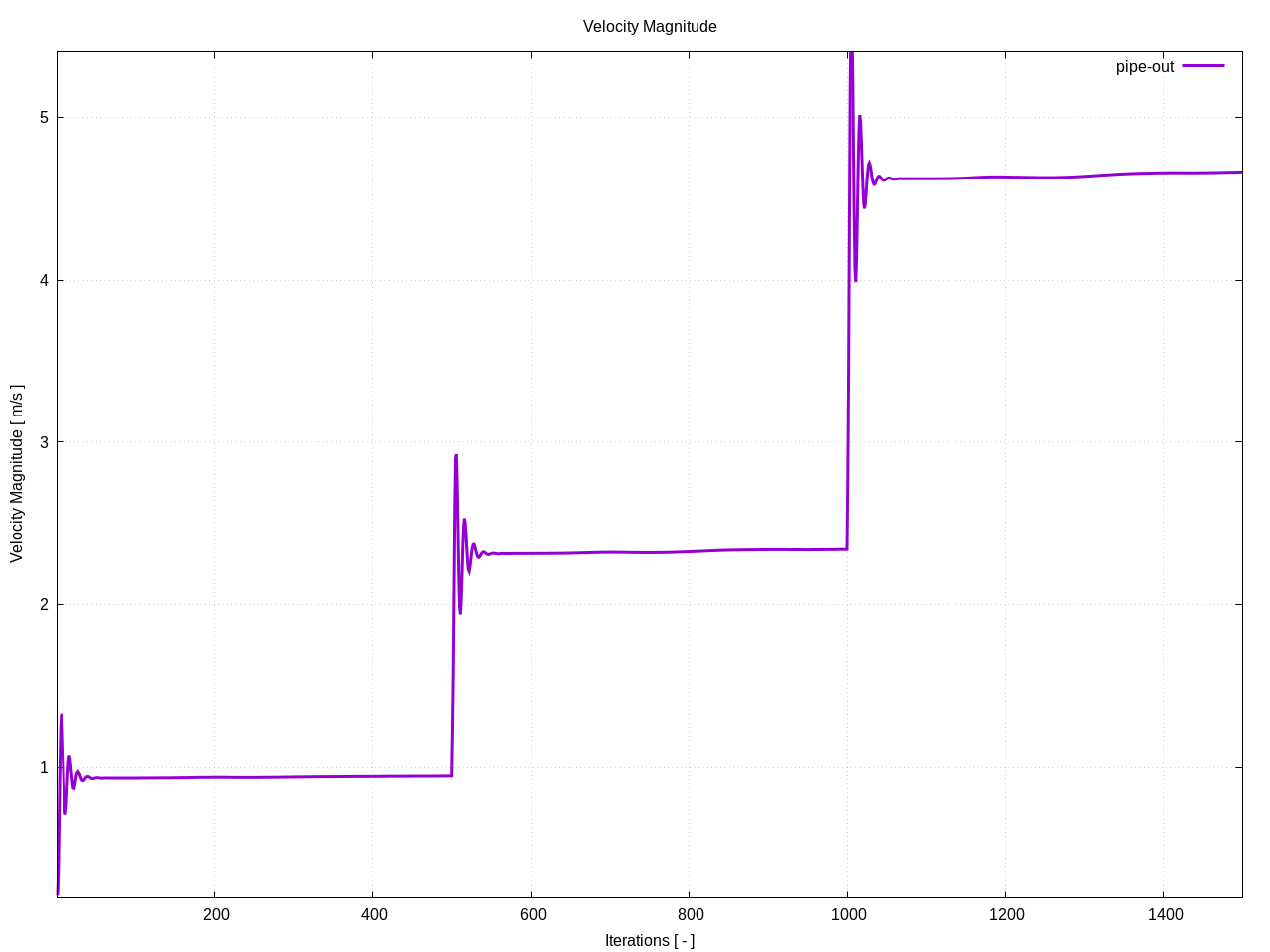

| Point |

flow rate |

bounding |

residuals |

| 1 |

|

|

|

| 2 |

|

|

|

| 3 |

|

|

|

|

| Average y+ at walls [ – ] |

details |

|

y+ details:

| Point |

Patch |

Min |

Max |

Avg |

| 1 |

pipe_pipe-wall_wall |

9.04389 |

14.8324 |

12.1009 |

| 2 |

pipe_pipe-wall_wall |

12.2621 |

31.6193 |

24.2141 |

| 3 |

pipe_pipe-wall_wall |

23.4782 |

58.7409 |

45.5498 |

|

| Wall-clock time [ hh:mm:ss ] |

00:00:02 (meshing)

00:00:59 (calculation)

|

| Parallel Processors [ – ] |

6 |

| Fluid Name |

water |

| Physical Model |

incompressible |

| Numerical order |

second |

| Turbulence model |

kOmegaSST |