Previous: Creating the Inlet Part Up: SALOME example – Cyclone Next: Split Each Part to

This is an automatically generated documentation by LaTeX2HTML utility. In case of any issue, please, contact us at info@cfdsupport.com.

Splitting Each Part to Perfect Fit - Inlet-extrusion

To achieve a perfect connection between the Inlet-extrusion and the Cyclone-rotPart a small modification has to be done. Let’s start with the Inlet-extrusion.

- At first the Inlet-extrusion will be split.

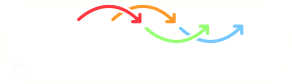

- Navigate to the menu Operations > Partition and set the following entries (see Fig.

):

):- Rename parameter Name to Inlet-body-part.

- Set Objects to Inlet-extrusion.

- Set Tool Objects to Cyclone-rotPart.

- Resulting type is Shell.

- Click Apply and Close.

Figure: Inlet-extrusion partitioning.

- Afterwards, the new Shell contains only the outer parts of Inlet-body-part will be created.

- At first, the new Faces from the Inlet-body-part are created.

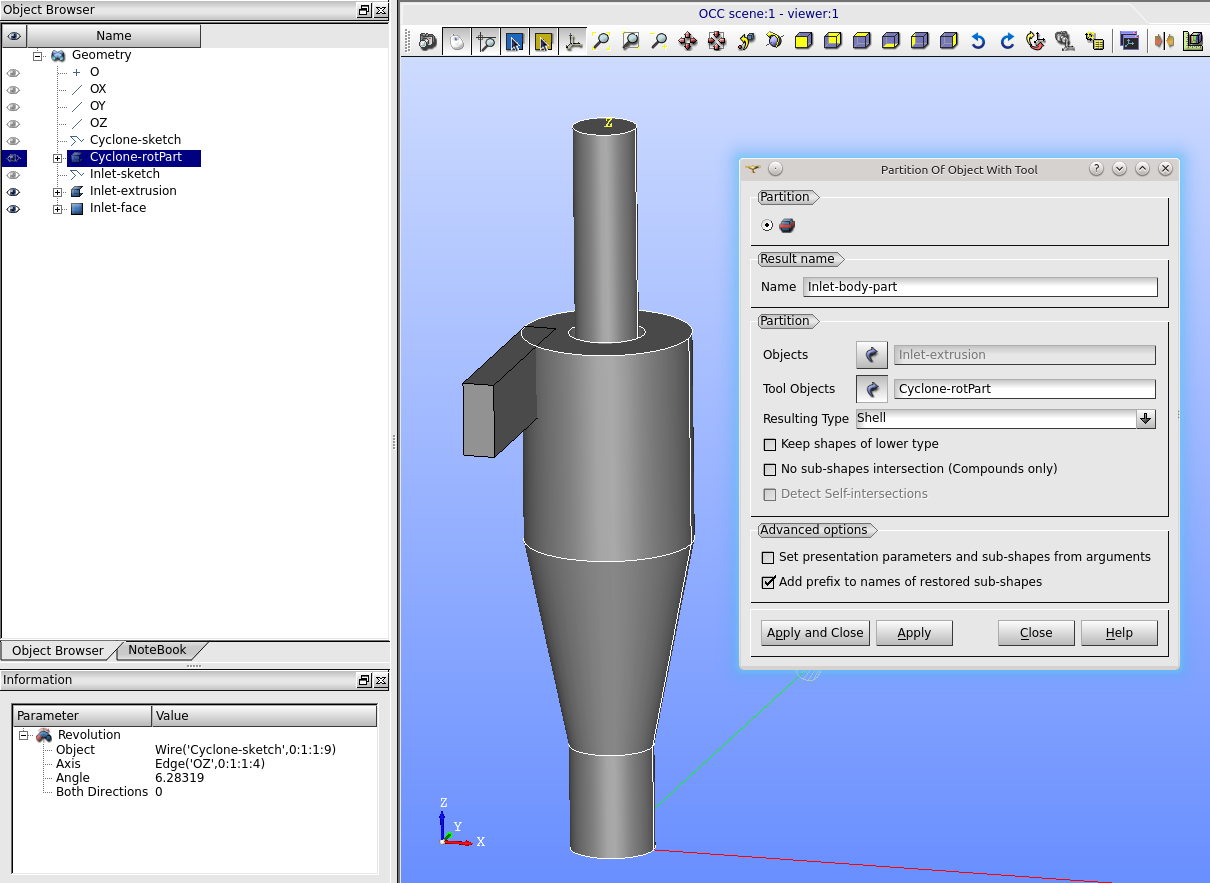

- Navigate to the menu New Entity > Explode and do the following steps (see Fig.

):

):- Set Main Object to Inlet-body-part.

- Check the Select Sub-Shapes option.

- By holding the Shift key on your keyboard and clicking on desired parts, i.e. 4 faces which are not inside the Cyclone-rotPart.

- Click Apply and Close.

Figure: Creating the new faces byExplode Tool.

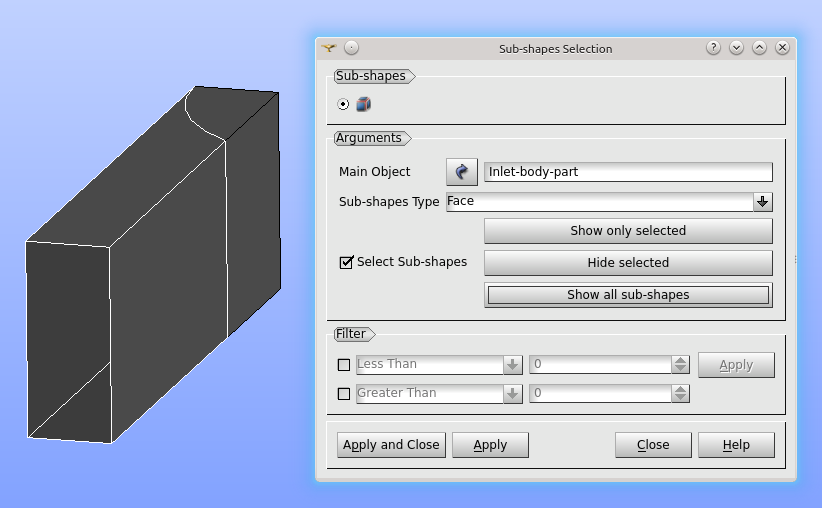

- Finally, the new shell is created using those faces from the previous step.

- Navigate to the menu New Entity > Build > Shell and follow these steps (see Fig.

):

):- Rename Name to Inlet-body-final.

- In the Objects select those faces mentioned in the previous step. Click them (holding Shift key) in the viewer.

- The other way to that is to select these faces in the Object Browser by clicking and holding Ctrl key.

- Click Apply and Close.

Figure: Creating a new Shell.