Previous: When using terminal: Up: TCFD-manual Next: Flow path geometry

This is an automatically generated documentation by LaTeX2HTML utility. In case of any issue, please, contact us at info@cfdsupport.com.

TCFD® - Input geometry

This chapter mainly deals with requirements for input data and its fundamental properties which have to be satisfied to get outstanding results with TCFD workflow. Moreover, basic terminology for input mesh data and turbomachinery simulations are introduced.

workflow. Moreover, basic terminology for input mesh data and turbomachinery simulations are introduced.

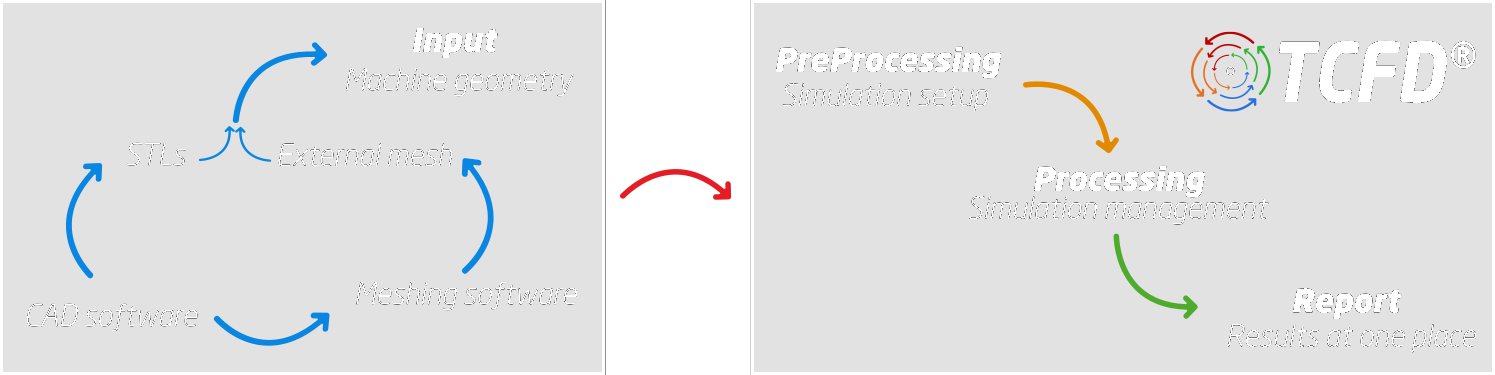

Figure above shows a simplified TCFD workflow. It emphasizes that input geometry preparation is a separate process from TCFD

workflow. It emphasizes that input geometry preparation is a separate process from TCFD . It has significant influence on results quality; wrong input generates wrong result. Make always sure that your input geometry, either STL files or external meshes, has the best possible quality. The main quality parameters and common errors will be presented later on in this Section.

Typically, the geometry is created or modified in some CAD software. Afterwards, TCFD

. It has significant influence on results quality; wrong input generates wrong result. Make always sure that your input geometry, either STL files or external meshes, has the best possible quality. The main quality parameters and common errors will be presented later on in this Section.

Typically, the geometry is created or modified in some CAD software. Afterwards, TCFD users have two basic options:

users have two basic options:

- Import the CAD geometry into some meshing program and generate the computation mesh. The resulting mesh (in *.msh format) can be directly imported into TCFD

.

. - Generate and export STL geometry from the CAD software and import the STL geometry into TCFD

.

.

Previous: When using terminal: Up: TCFD-manual Next: Flow path geometry